_____________

REELMASTER® 216-D Daily Maintenance Check List

Unit Designation:__________

Daily Maintenance:

(duplicate this page for routine use)

TORO ID#:_______-_______

Maintenance Check Item

Daily Maintenance Check For Week Of

MON

_______HRS

TUES

_______HRS

WED

_______HRS

THURS

_______HRS

FRI

_______HRS

SAT

_______HRS

SUN

_______HRS

Safety Interlock Operation

Brake Operation

Engine Oil Level

Cooling System Fluid Level

Drain Water/Fuel Separator

Air Filter, Dust Cup, Baffle

Radiator & Screen for Debris

Unusual Engine Noises

1

Unusual Operating Noises

Hydraulic System Oil Level

Hydraulic Hoses for Damage

Fluid Leaks

Fuel Level

Tire Pressure

Instrument Operation

Reel-to-Bedknife Adjustment

Height-of-Cut Adjustment

Cutting Unit Belt Adjustment

Lubricate All Grease Fittings

2

Touch-up damaged paint

1

= Check glow plug and injector nozzles, if hard starting, excess smoke, or rough running is noted.

2

= Immediately after every washing, regardless of the interval listed.

Inspection performed by:________________

Item

Date

Information

1

2

3

4

5

6

7

(See Operator's and Service Manual for specifications and procedures)

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

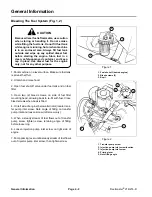

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

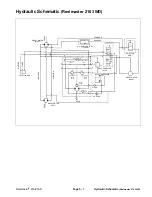

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...