Adjustments

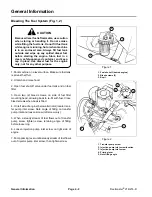

Carburetor Adjustments

Lack of power accompanied by black sooty exhaust

smoke is usually caused by a rich carburetor setting.

Since a dirty air cleaner element causes the same

conditions, check it before adjusting carburetor.

High RPM Setting

3600

±

100

Low RPM Setting

1200

±

100

IMPORTANT: Check to make sure the choke is op

erating correctly before the carburetor is adjusted.

1. Main fuel screw – Close screw by gently rotating it

clockwise.

IMPORTANT: Do not close the screw too tight be

cause the screw will likely be damaged.

2. Rotate – open – the main fuel screw 3-1/2 turns

counterclockwise.

3. Idle fuel adjusting screw – Close screw by gently

rotating it clockwise. Open screw by rotating it 2-1/2

turns counterclockwise.

Engine must be running so final adjustment

of the carburetor can be performed. To guard

against possible personal injury, keep hands,

feet, face and other parts of the body away

from the muffler, other hot parts of the engine,

and other moving or rotating parts of the

engine. Assure reel switch is in DISENGAGE

position and cutting units are on the shop

floor. Also engage parking brake.

IMPORTANT: Do not close the screw too tightly

CAUTION

because the screw will likely be damaged.

Note: These settings are approximate - however, the

settings will allow engine to be starter so carburetor can

be fine tuned – steps 4 - 7.

4. Start engine and let it run for 5 to 10 minutes at half

throttle to warm up. Engine must be warm before mak

ing final adjustments.

5. Move throttle to TRANSPORT position. Turn main

fuel screw in until speed decreases and note position of

screw. Now turn screw out – the engine speed may first

increase, then it will decrease as screw is turned. Note

the position of screw when engine speed starts to

decrease. Set the screw at the midpoint of the two

positions noted.

6. To adjust idle fuel adjusting screw, follow same pro

cedure as for main fuel but more throttle to IDLE after 5

to 10 minute warm up and make adjustment.

7. Idle Speed Setting – Run engine at half-throttle for 5

to 10 minutes to warm up. Move throttle to IDLE and set

engine speed to 1200 RPM by turning the idle speed

adjusting screw clockwise or counterclockwise.

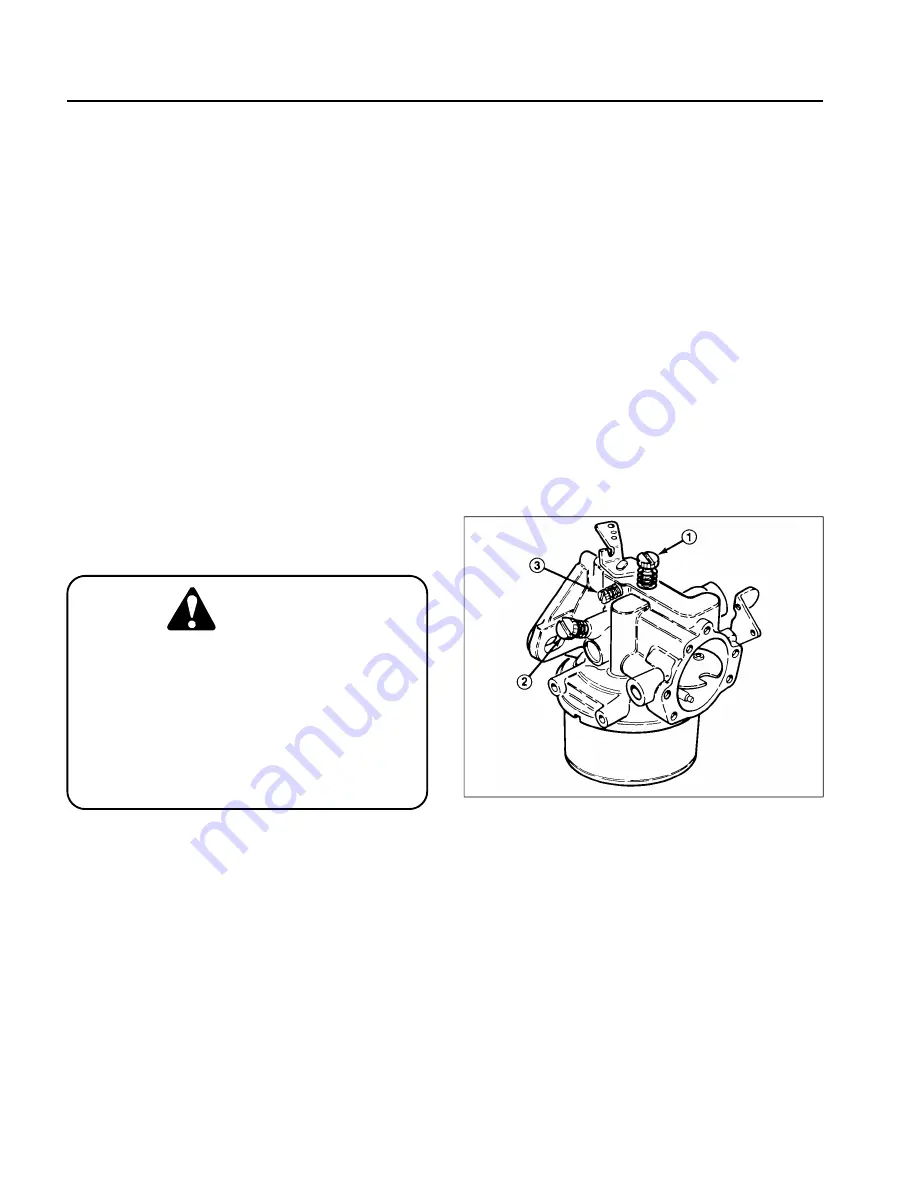

Figure 2

1. Main fuel screw

2. Idle fuel adjusting screw

3. Idle speed screw

Adjustments

Page 3 - 2

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

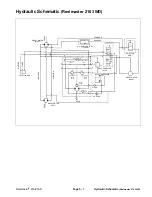

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...