TEST HOOK-UP NO. 1: Charge Pump Flow and Implement Relief Pressure (Fig. 14, 15, 16)

(Using Tester With Pressure and Flow Capabilities)

Tester Connection

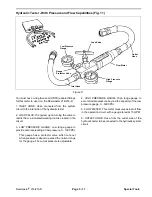

Connect tester in series between implement pressure

port of hydrostatic pump and pressure inlet port of lift

valve (Flow Control Open).

Reelmaster 216: Install tester between hose and

fitting at front of valve.

Reelmaster 216-D: Install tester between hose and

fitting at bottom front of pump.

TEST A: Charge Pump Flow and

Implement Relief Pressure

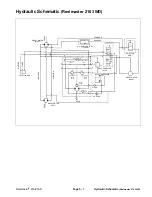

Figure 14

1. Operate engine at full speed:

Reelmaster 216 valve connections

Reelmaster 216:

3600

±

100 RPM

Reelmaster 216-D:

3200

±

100 RPM

2. Make sure hydraulic oil is at operating temperature.

3. Traction pedal and lift valve in neutral. Parking brake

engaged.

4. While watching flow and pressure gauges, slowly

close flow control valve until flow gauge reads 1 GPM.

TESTER READINGS: GPM Flow — Not less than 1

GPM at Minimum 500 PSI.

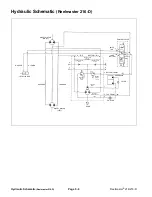

Figure 15

Reelmaster 216-D pump connections

CAUTION

Implement relief pressure should not exceed

800 PSI.

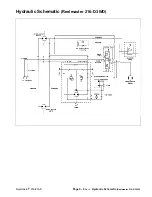

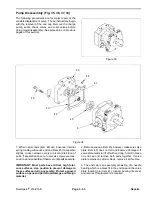

Figure 16

(Reelmaster 216 2WD shown)

Testing

Page 5 - 18

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...