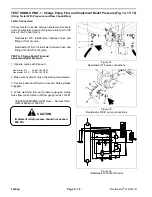

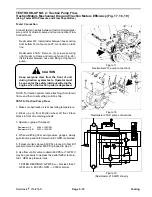

Test Hook-up No. 4: Traction Pressure (Fig. 21)

Gauge Connection

Connect a 10,000 PSI hydraulic pressure gauge to

forward traction pressure gauge port.

TEST A: Traction Pressure

1. Make sure pump drive belt is properly adjusted and

in good condition.

2. Make sure hydraulic oil is at operating temperature.

3. Operate engine at full speed:

Reelmaster 216:

3600

±

100 RPM

Reelmaster 216-D:

3200

±

100 RPM

4. Attach a heavy chain to rear frame of machine and

then to something solid in shop. Engage parking brake.

CAUTION

Keep everyone clear from the front of unit

during traction system tests. Operator must

be on seat or the safety interlock will stop the

engine when the traction pedal is depressed.

Figure 21

1

1. 10,000 PSI hydraulic pressure gauge

5. While watching pressure gauges, slowly push traction

pedal into forward until maximum pressure is obtained.

GAUGE READING: 4000 – 4500 PSI.

Testing

Page 5 - 22

Rev. A

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...