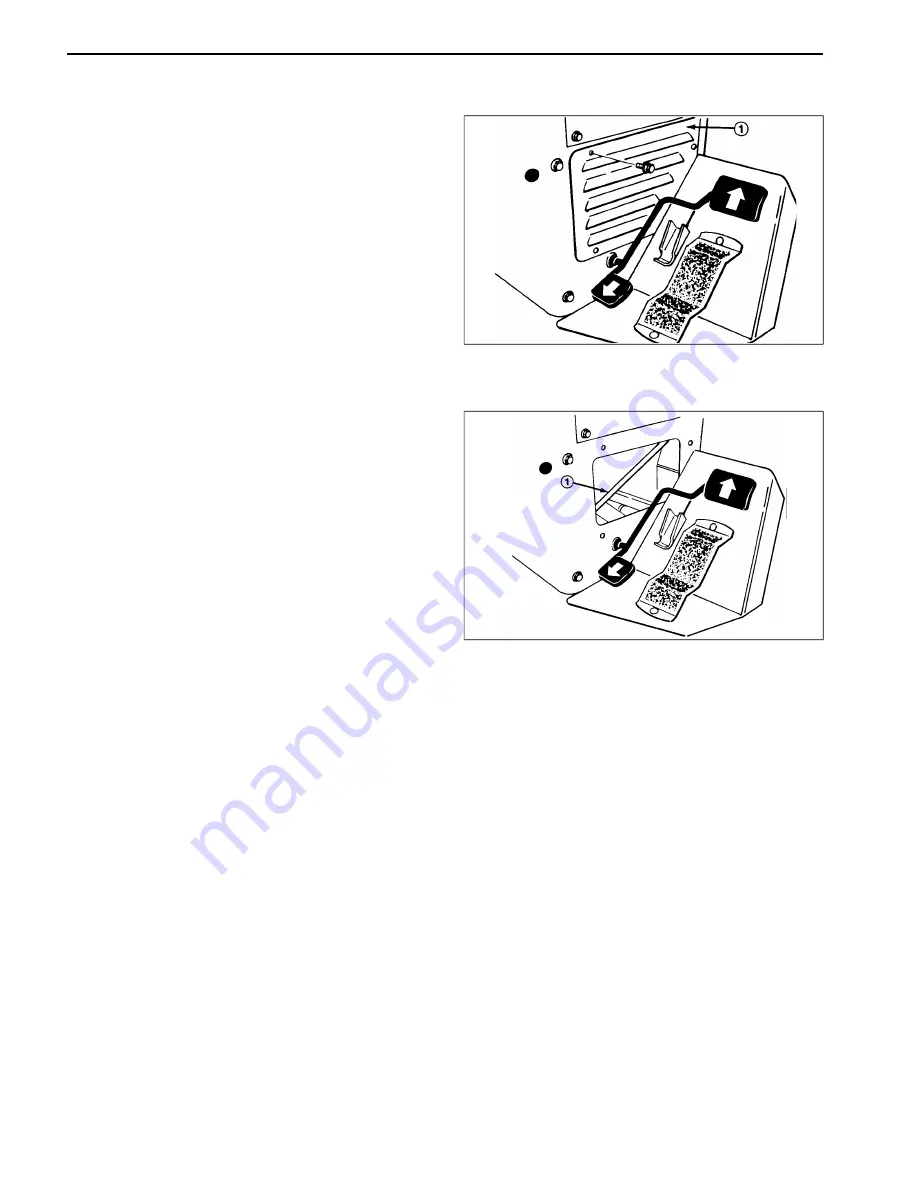

Adjusting Tracton Pedal

(Reelmaster 216)

(Fig. 26, 27)

If traction pedal contacts footrest when pushed fully

forward or you cannot get maximum forward traction

speed, an adjustment to the traction pedal linkage is

required. There should be 3/8 inch clearance between

pedal shaft and footrest when pedal is pushed fully

forward.

1. Remove (3) self-tapping screws securing support

screen to hydraulic support panel. Remove screen.

2. Loosen jam nuts on each end of traction rod.

3. Rotate rod to get a dimension of 3/8 inch between

traction pedal shaft and R.H. footrest when pedal is

pushed fully forward.

Figure 26

4. Re-tighten jam nuts securing traction rod and reinstall

1. Support screen

support screen.

5. The stop for reverse travel (under pedal) may be

adjusted for slower travel. Speeds in excess of 3 M.P.H.

are not recommended.

Figure 27

1. Traction rod

Adjustments

Page 5 - 26

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...