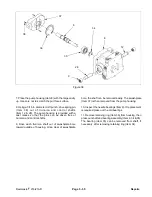

Pump Belt Adjustment (Fig. 30)

Make sure belts are properly tensioned to assure proper

operation ot the machine and unnecessary wear. Check

belt midway in span of belt. Check tension again on new

belts after 8 hours of operation.

Tighten nut on adjustment rod until desired belt tension

is attained. Belt should be tightened to 140 lbs. of

tension.

NOTE: Tighten belt to eliminate slippage (squeeling

under load) but do not overtighten.

Figure 30

1. Nut

2. Adjustment rod

Adjustments

Page 5 - 28

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...