8

39

5

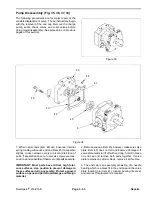

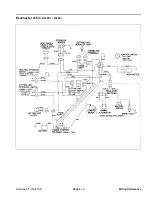

Figure 37

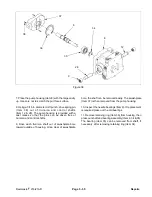

4. Lift out the cylinder block assembly (Item 5). The

5. Visually inspect wear surfaces of valve plate, cylinder

pistons may come out of the cylinder block. There is no

block and slippers for damage. Check to be sure pistons

special orientation of piston to bore that needs to be

are free in bores.

maintained. Do not attempt to disassemble the spring

and other parts from the center bore of the cylinder

6. Remove thrust plate (Item 39) from counterbore in

block. The entire cylinder block assembly (Item 5)

face of swashplate (Item 37). Visually inspect both sides

should be replaced if any of its components are dam-

for damage and flatness.

aged.

Repairs

Page 5 - 34

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...