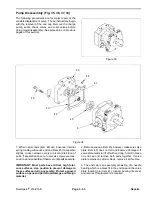

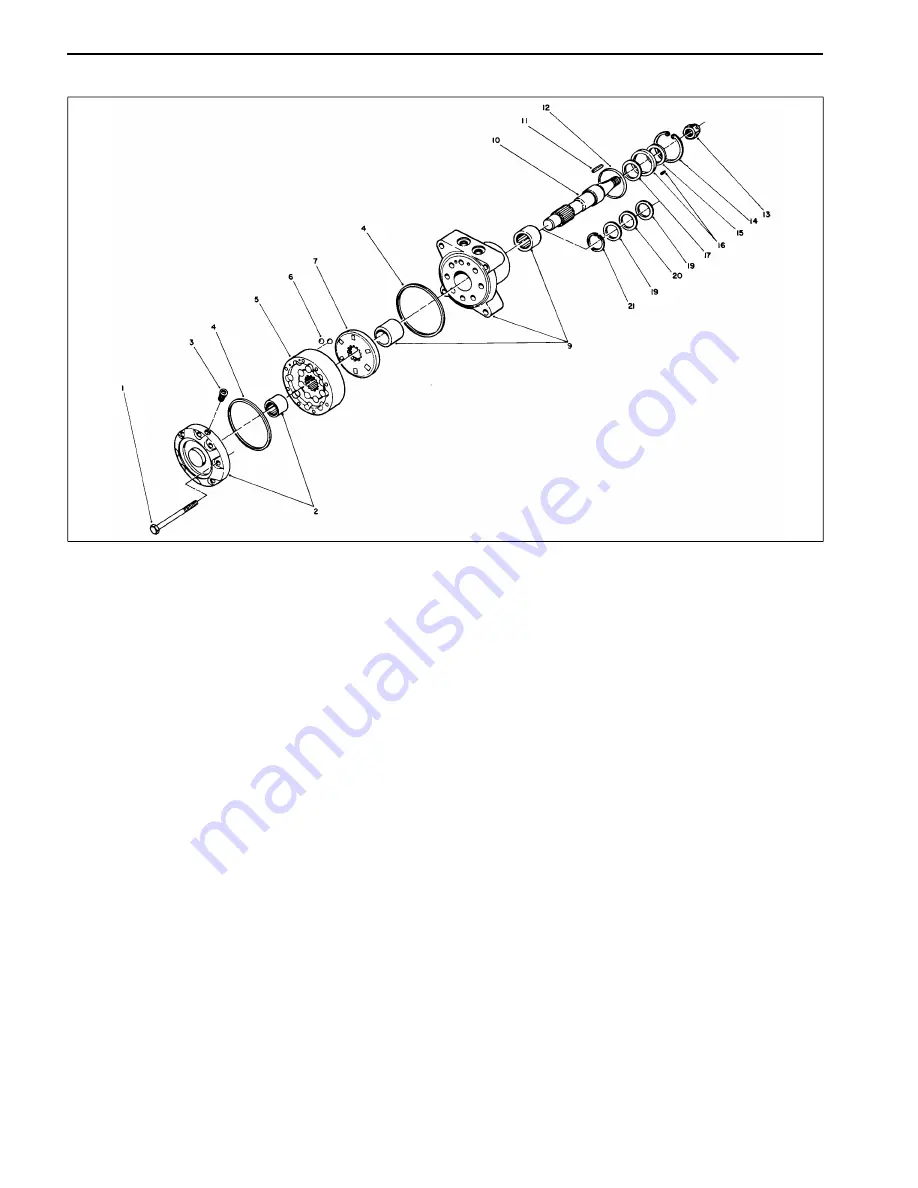

Wheel Motor (Fig. 43)

1. Screw

2. Cover & bearing ass’y

3. Plug

4. Seal

5. IGR assembly

6. Check ball

Figure 43

9. Body & bearing assembly

10. Shaft

11. Key

12. O-ring

13. Nut

14. Snap ring

15. Dust seal

16. Retainer pin

17. Lip seal

19. Thrust washer

20. Thrust bearing

21. Snap ring

7. Valve plate

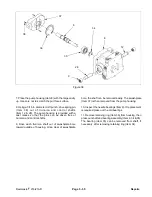

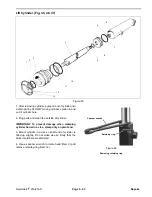

Disassembly of Shaft and Front Seal Assembly

1. Put the motor on a clean, flat surface with the shaft

facing up. Clean the front end of the motor to avoid

contaminating the internal parts during the procedure.

2. Remove key (Item 11) from the shaft.

3. Remove the snap ring (Item 14) using a snap ring

pliers.

4. Pull the shaft (Item 10) out vertically.

IMPORTANT: When pulling shaft vertically, do not

rotate the shaft or move the motor as this may alter

internal timing.

5. With the seal retainer assembly and shaft assembly

removed, remove all the parts from the shaft and inspect

the various parts of the seal assembly (Item 15, 16, 17),

shaft (Item 10) and thrust bearing assembly (Item 19,

20, 21). Replace any worn or damaged parts. Always

replace the seal retainer assembly (Item 15, 16, 17). The

shaft should have smooth polished surfaces in the

bearing and seal areas. If the shaft is lightly scratched

in these areas, polish with fine emery paper in a circum

ferential direction. However, if the shaft has any pitting

or deep scratches, the entire motor should be disassem

bled for inspection.

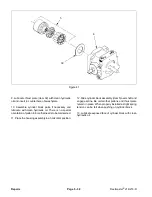

Assembly of Shaft and Front Seal Assembly

1. Assemble the thrust washers (Item 19) and thrust

bearing (Item 20) on the shaft using the snap ring (Item

21). The snap ring sharp edges MUST face away from

the thrust washers with the thrust bearing (Item 20)

between the washers.

2. Slowly lower the spline end of the shaft (Item 10)

assembly into the motor body using caution not to rotate

the internal parts once the shaft spline starts to engage.

3. Put the lightly oiled o-ring (Item 12) into the groove in

the body bore.

Repairs

Page 5 - 40

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...