Lift Cylinder (Fig. 45, 46, 47)

1

2

3

4

5

6

7

8

9

10

11

12

13

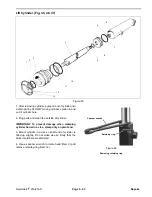

Figure 45

1. After removing cylinder, pump oil out of cylinder into

a drain pan by SLOWLY moving cylinder’s piston in and

out of cylinder bore.

2. Plug ports and clean the outside of cylinder.

IMPORTANT: To prevent damage when clamping

cylinder barrel in a vise, clamp only on pivot end.

3. Mount cylinder in a vise so shaft end of cylinder is

tilted up slightly. Do not close vise so firmly that the

barrel could become distorted.

4. Use a spanner wrench to rotate head (Item 3) and

remove retaining ring (Item 12).

Figure 46

Retaining ring

Spanner wrench

Removing retaining ring

Reelmaster

®

216/216-D

Page 5 - 43

Repairs

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...