Verify Interlock System Operation

The purpose of the interlock system is to prevent the

engine from cranking or starting unless the traction

pedal is in NEUTRAL and the cutting unit engagement

switch is DISENGAGED. In addition, the engine will stop

when the cutting unit engagement switch is engaged or

traction pedal is depressed with the operator off the

seat.

The interlock switches are for the operator’s

protection, so do not disconnect them. Check

operation of the switches daily to assure in

terlock system is operating. If a switch is

defective, replace it before operating. Regard

less if switches are operating properly or not,

replace them every two years to assure maxi

mum safety. do not rely entirely on safety

switches - use common sense!

CAUTION

To check interlock system operation:

1. Move machine to a wide open area free of debris and

bystanders. Raise cutting units and stop engine. En

gage parking brake.

2. Sit on seat. Move Reel Drive switch to ENGAGE

position. Try to start engine. If engine cranks, there may

be a malfunction in interlock system. Repair immedi

ately. If engine does not crank, proceed to step 3.

3. Sit on seat. Depress traction pedal in forward and

reverse directions while trying to start engine. If engine

cranks while pedal is in forward or reverse position,

there may be a malfunction in interlock system. Repair

immediately. If engine does not crank, proceed to

step 4.

4. With cutting units in raised position, sit on seat and

start engine. Move Reel Drive switch to ENGAGE posi

tion. Lower cutting units to ground. Cutting unit reels

should start turning when cutting units are lowered.

Raise cutting units and verify that they stop. If they do

not stop, there may be a malfunction in interlock system.

Repair immediately. If cutting units stop, proceed to

step 5.

5. While sitting on seat with cutting units in raised

position and engine running, move Reel Drive switch to

ENGAGE position. Hold on to steering wheel and raise

up off of seat. Engine should stop. If engine does not

stop, there is a malfunction in interlock system. Repair

immediately. If engine stops, seat switch is operating

correctly.

Reelmaster

®

216/216-D

Page 6 - 13

Troubleshooting

(Reelmaster 216)

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

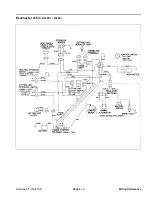

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

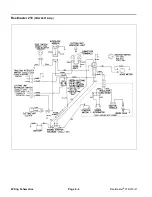

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...