Traction (Neutral) Switch (Fig. 8)

The traction switch is normally open and closes when

traction pedal is in neutral.

IMPORTANT: The traction switch has three (3) ter

minals. Make sure the wires are connected to the

“COMMON” and “N.O.” terminals.

Test switch by disconnecting wires from switch termi

nals and connecting a continuity tester across COM-

MON and N.O. terminals. With engine off, slowly push

traction pedal in forward and reverse direction while

watching continuity tester. There should be indications

that traction switch is opening and closing. Allow traction

pedal to return to neutral. There should be continuity

across the terminals. (See Replacing Traction Switch in

Repairs section of this chapter for replacement and

adjustment procedures.)

NOTE: Apply “Loctite 271” or equivalent to threads of

switch screws before installing.

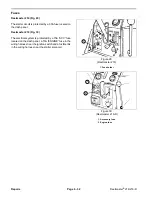

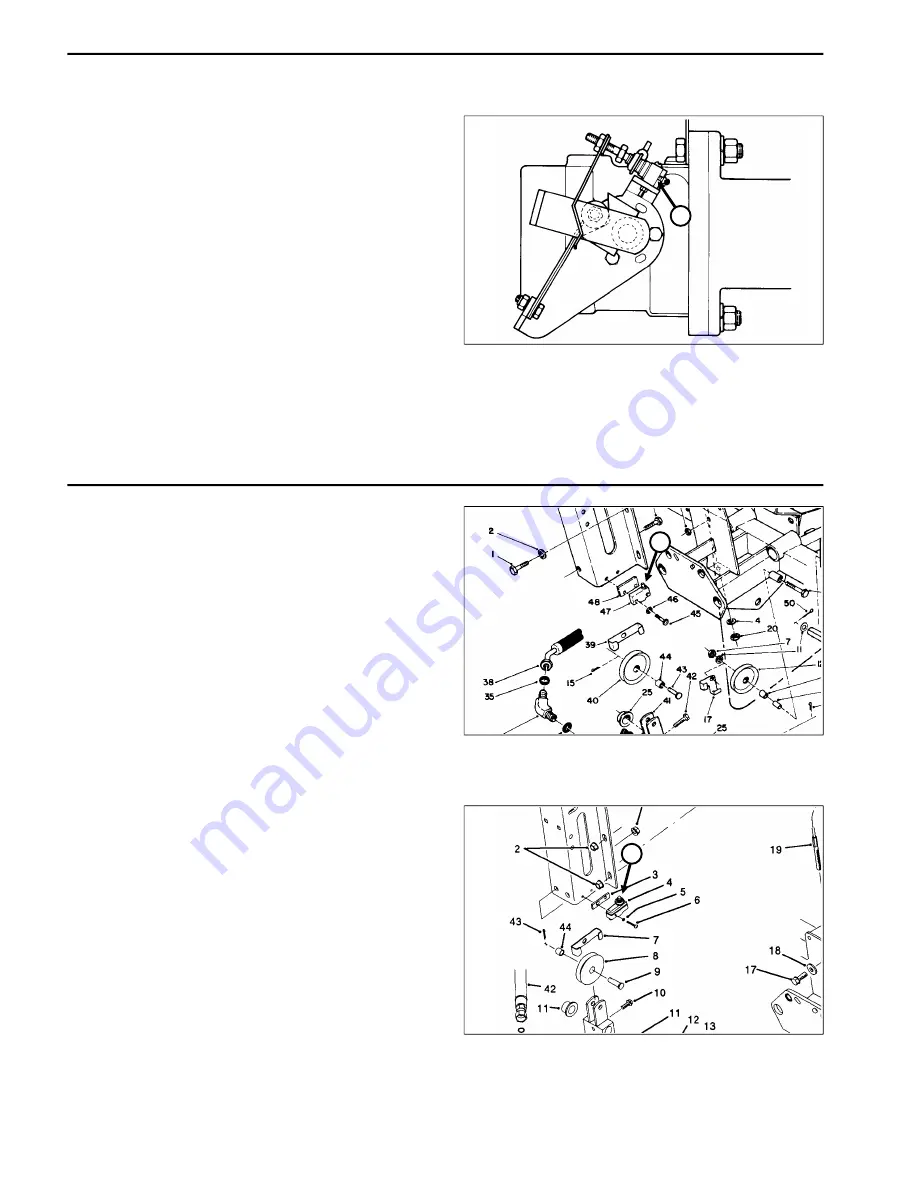

Cutting Unit Interlock Switch (Fig. 9, 10)

The cutting unit interlock switch is normally open and

closes with the lift cylinder is retracted (cutting units

lowered).

IMPORTANT: The traction switch has three (3) ter

minals. Make sure the wires are connected to the

“COMMON” and “N.O.” terminals.

Test the switch by disconnecting the wires from the

switch terminals and connecting a continuity tester

across the COMMON and N.O. terminals. With the

cutting units lowered and lift cylinder fully retracted,

there should be continuity across the terminals. With the

cutting units raised and lift cylinder extended there

should be no continuity across the terminals. (See Re

placing the Cutting Unit Interlock Switch in the Repairs

section of this chapter for replacement procedures).

NOTE: Apply “Loctite 271” or equivalent to threads of

switch screws before installing.

1

Figure 8

1. Traction (neutral) switch

1

Figure 9

(Reelmaster 216)

1. Cutting unit interlock switch (Item 47)

1

Figure 10

(Reelmaster 216-D)

1. Cutting unit interlock switch (Item 4)

Testing

Page 6 - 22

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...