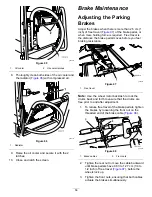

g376007

Figure 101

1.

Full mark (dipstick)

2.

Add mark (dipstick)

3.

Remove the cap/dipstick from the filler neck and

wipe it with a clean rag.

4.

Insert the dipstick into the filler neck; then

remove it and check the level of fluid.

Note:

The fluid level should be within operating

range on the dipstick.

Important:

Do not overfill the tank.

5.

If the level is low, add the appropriate amount of

fluid to raise the level to the full mark.

6.

Install the cap/dipstick onto the filler neck.

Checking the Hydraulic

Lines and Hoses

Service Interval:

Before each use or daily

Check the hydraulic lines and hoses for leaks, kinked

lines, loose mounting supports, wear, loose fittings,

weather deterioration, and chemical deterioration.

Make all necessary repairs before operating.

Replacing the Hydraulic

Filters

Service Interval:

Every 1,000 hours—

If you

are using the recommended

hydraulic fluid,

replace the

return-hydraulic filter and

charge-hydraulic filter.

Every 800 hours—

If you are not using the

recommended hydraulic fluid or have

ever filled the reservoir with an alternative

fluid,

replace the return-hydraulic filter and

charge-hydraulic filter.

Important:

Use of any other filters may void the

warranty on some components.

Changing the Return Filter

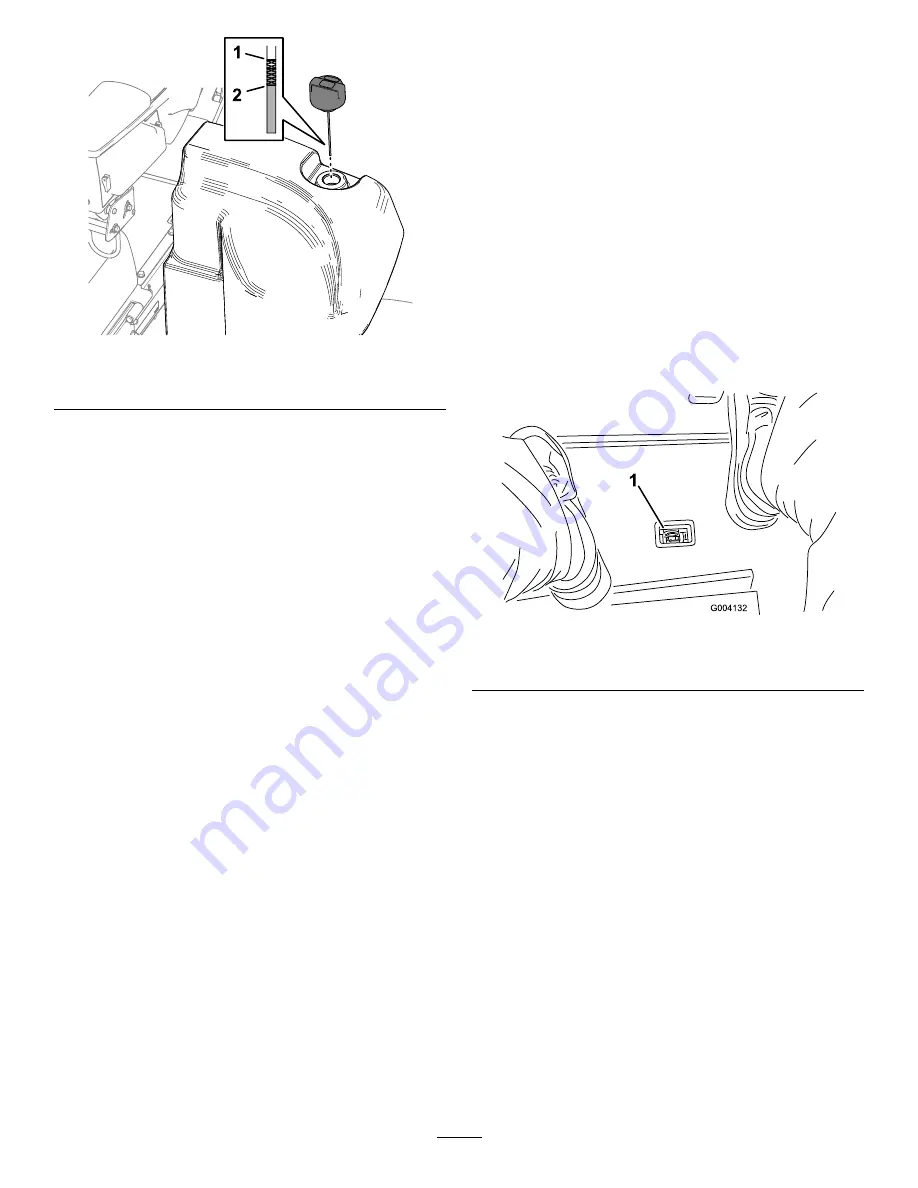

The hydraulic system is equipped with a return

filter-service indicator (

). You view

the filter-service indicator through the hole in the

floor plate. With the engine running at operating

temperature, check the color of the indicator as

follows:

•

Green indicates normal hydraulic-fluid flow through

the filter.

•

Ref indicates a restricted filter. Change the return

filter.

g004132

Figure 102

1.

Hydraulic-filter-restriction indicator

1.

Prepare the machine for maintenance; refer to

Preparing for Maintenance (page 40)

.

2.

At the front of the machine, align a drain pan

under the return filter (

).

59

Summary of Contents for Reelmaster 5610

Page 68: ......