Rev. B

CAUTION

Reelmaster 6500–D/6700–D

Page 4 – 37.2

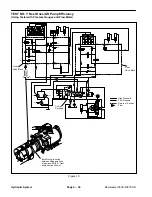

Hydraulic System

1. Make sure hydraulic oil is at normal operating temper-

ature before doing test.

Keep away from reels during tests to prevent

personal injury from rotating reel blades. Do

not stand in front of the machine.

2. Determine which reel motor is malfunctioning.

One way to find a bad motor is to have another per-

son observe the machine while mowing in dense

turf. A bad motor will run slower, produce fewer clip-

pings and could cause marcelling (or a washboard

appearance) of the turf.

NOTE: The three reel motors in the front circuit (No. 1,

4 and 5) and two reel motors in the rear circuit (No. 2 and

3) are connected in series (No. 2, 3, 6 and 7 on

RM6700–D). To isolate a faulty motor you may have to

test all motors in the circuit, starting with the first one in

series.

3. Lower cutting units, engage parking brake and stop

the engine.

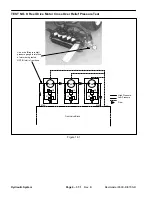

4. Install a tee fitting between the motor inlet fitting and

hose. Install a 5000 PSI pressure gauge on the tee fit-

ting.

5. Set HOC Selector Knob, located under the instru-

ment panel, to position A (full speed). Make sure Back-

lap switch is OFF.

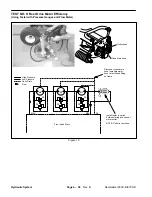

6. Put a block of wood between the blades of the cutting

unit being tested to prevent the reel from rotating.

7. One person should sit on the seat and operate the

machine while another person reads the tester. Start the

engine and move “Enable/Disable” switch to ENABLE.

Move “Lower–Mow/Raise” lever forward to engage the

cutting units.

TESTER READING: Approx. 1400 – 1600 PSI.

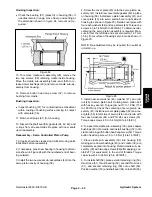

8. Disengage the cutting units and stop the engine. If

pressure is less than 1400 PSI, crossover relief valve on

motor is malfunctioning or there is internal leakage in the

reel motor and the motor efficiency should be checked.

Hydraulic System

Summary of Contents for REELMASTER 6500 D

Page 2: ...Reelmaster 6500 D 6700 D ...

Page 4: ...Reelmaster 6500 D 6700 D ...

Page 10: ...Reelmaster 6500 D 6700 D Page 1 6 Safety ...

Page 12: ...Reelmaster 6500 D 6700 D Page 2 2 Product Records and Manuals Equivalents and Conversions ...

Page 20: ...Rev C Reelmaster 6500 D 6700 D Page 2 10 Product Records and Manuals ...

Page 24: ...Rev C Reelmaster 6500 D 6700 D Page 2 14 Product Records and Manuals ...

Page 86: ...Engine Page 3 62 Reelmaster 6500 D 6700 D ...

Page 202: ...Reelmaster 6500 D 6700 D Page 5 8 2 Electrical System Rev C This page is intentionally blank ...

Page 226: ...Reelmaster 6500 D 6700 D Page 5 26 6 Electrical System Rev B This page is blank ...

Page 276: ...Reelmaster 6500 D 6700 D Page 6 22 Axles Planetaries and Brakes ...

Page 300: ...Reelmaster 6500 D 6700 D Page 7 24 Cutting Units Rev B Model 03853 Model 03854 Model 03855 ...