Reelmaster 6500–D/6700–D

Page 4 – 45

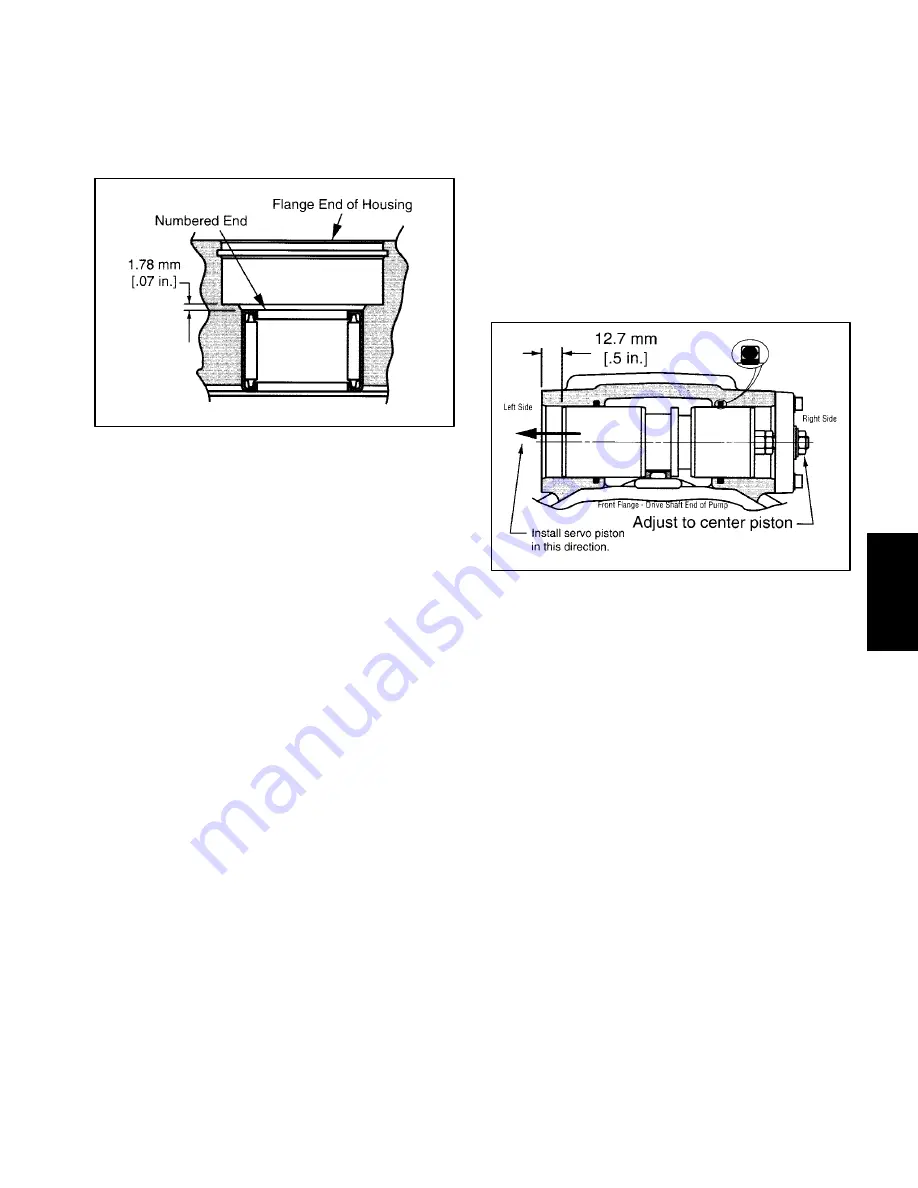

Hydraulic System

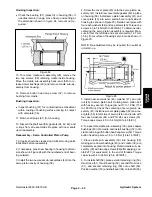

Housing Inspection:

Check the bearing (57) (press fit) in housing (58). If

needles remain in cage, move freely, and setting at

the dimension shown in figure 24, removal not re-

quired.

Figure 24

15. To remove cradle sub–assembly (39), remove the

two cap screws (38) retaining cradle inside housing.

Move the cradle sub–assembly back–and–forth to re-

lease dowel bushings (40) and remove cradle sub–as-

sembly from housing.

16. Remove button head cap screw (32) to remove

bushing from cradle.

Bushing Inspection:

Inspect bushing (37) for contamination embedment

within coating of bushing surface coming in contact

with camplate (36).

17. Remove all plugs (61) from housing.

18. Discard the shaft seal (54), gaskets (34, 42, 62), and

o–rings from all assemblies. Replace with new seals

upon reassembly.

Reassembly – Servo Controlled Piston Pump

1. All parts should be cleaned and critical moving parts

lubricated before reassembly.

2. If necessary, press new bearing in housing to dimen-

sion shown in Figure 24 with the numbered end of bear-

ing outward.

3. Install the two new seal sub–assemblies (49) into the

servo piston cavity of housing (58).

4. Screw the cover plate (43) onto the servo piston as-

sembly (41). Install new cover plate gasket (42) in place

on housing (58). Install servo piston assembly (41) and

cover plate (43) into servo piston bore in right side of

housing (as shown in Figure 25). Retain cover plate with

four each washers (44) and cap screws (45). Torque cap

screws 4.5 to 5.4 Nm [40 to 48 Ibf

S

in.]. To obtain neutral,

centering the servo piston assembly is required. Mea-

sure in from the left side and set servo piston 12.7 mm

[.5 in.] from surface of housing servo bore as shown in

Figure 25.

NOTE: Re–adjustment may be required for neutral at

unit start–up.

Figure 25

5. Install new seal washer (48), washer (47), and jam

nut (46) to servo piston bolt. Holding servo piston bolt

with hex key wrench. Torque jam nut 17 to 18 Nm [150

to 160 Ibf

S

in]. Check the centering of servo piston as-

sembly (41). Install new cover plate gasket (42) and cov-

er plate (59) to left side of servo piston and retain with

four each washers (44) and #10–24 cap screws (45).

Torque cap screws 4.5 to 5.4 Nm [40 to 48 Ibf

S

in.].

6. To assemble cradle sub–assembly (39), press dowel

bushings (40) into cradle and install bushing (37) onto

cradle retaining with button head cap screw (32). Torque

button head cap screw 1.6 to 1.8 Nm [14 to 16 Ibf

S

ft.]

7. Place cradle sub–assembly (39) into housing (58)

making sure dowel bushings (40) and cradle (39) are

completely seated into housing. Retain cradle sub–as-

sembly (39) with two cap screws (38) after applying Loc-

tite #277 (or equivalent) to the end of threads. Torque

cap screws 34 to 38 Nm [25 to 28 Ibf

S

ft.].

8. To install shaft (56), place exterior retaining ring (50),

thrust race (51), thrust bearing (52), second thrust race

(51), and second retaining ring (50) onto shaft (56).

Position washer (53) and shaft seal (54) onto shaft (56).

Hydraulic System

Summary of Contents for REELMASTER 6500 D

Page 2: ...Reelmaster 6500 D 6700 D ...

Page 4: ...Reelmaster 6500 D 6700 D ...

Page 10: ...Reelmaster 6500 D 6700 D Page 1 6 Safety ...

Page 12: ...Reelmaster 6500 D 6700 D Page 2 2 Product Records and Manuals Equivalents and Conversions ...

Page 20: ...Rev C Reelmaster 6500 D 6700 D Page 2 10 Product Records and Manuals ...

Page 24: ...Rev C Reelmaster 6500 D 6700 D Page 2 14 Product Records and Manuals ...

Page 86: ...Engine Page 3 62 Reelmaster 6500 D 6700 D ...

Page 202: ...Reelmaster 6500 D 6700 D Page 5 8 2 Electrical System Rev C This page is intentionally blank ...

Page 226: ...Reelmaster 6500 D 6700 D Page 5 26 6 Electrical System Rev B This page is blank ...

Page 276: ...Reelmaster 6500 D 6700 D Page 6 22 Axles Planetaries and Brakes ...

Page 300: ...Reelmaster 6500 D 6700 D Page 7 24 Cutting Units Rev B Model 03853 Model 03854 Model 03855 ...