Rev. B

Reelmaster 6500–D/6700–D

Page 5 – 26

Electrical System

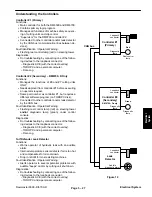

4. Turn the key switch to the ON position, but do not start

machine.

Note: The red text on the overlay decal refers to input

switches and the green text refers to outputs.

5. The “outputs displayed” LED, on lower right column

of Diagnostic ACE, should be illuminated. If “inputs dis-

played” LED is illuminated, press the toggle button, on

Diagnostic ACE, to change LED to “outputs displayed”.

Note: It may be necessary to toggle between “inputs dis-

played” and “outputs displayed” several times to do the

following step. To toggle back and forth, press toggle

button once. This may be done as often as required. DO

NOT HOLD BUTTON.

6. Sit on the seat and attempt to operate the desired

function of the machine. The appropriate output LED’s

should illuminate to indicate that the ECU is turning on

that function. (Refer to the list on page 21 to be certain

of the specified output LED’s.

Note: If any output LED is blinking, this indicates an

electrical problem with that OUTPUT. Repair / replace

defective electrical parts immediately. To reset a blinking

LED, turn the key switch “OFF”, then back “ON”.

If no output LED’s are blinking, but the correct output

LED’s do not illuminate, verify that the required input

switches are in the necessary positions to allow that

function to occur. Verify correct switch function.

If the output LED’s are on as specified, but the machine

does not function properly, this indicates a non–electri-

cal problem. Repair as necessary.

Note: Due to electrical system constraints, the output

LED’s for “START”, “PREHEAT” and “ETR/ALT” may not

blink even though an electrical problem may exist for

those functions. If the machine problem appears to be

with one of these functions, be certain to check the elec-

trical circuit with a volt / ohm meter to verify that no elec-

trical problem exists to these functions.

If each input switch is in the correct position and func-

tioning correctly, but the output LED’s are not correctly

illuminated, this indicates an ECU problem. If this oc-

curs, contact your Toro Distributor for assistance.

IMPORTANT: The Diagnostic ACE displays must not

be left connected to the machine. It is not designed

to withstand the environment of the machine’s ev-

ery day use. When done using Diagnostic ACE, dis-

connect them from the machine and reconnect

loopback connectors to harness connectors. Ma-

chine will not operate without loopback connectors

installed on harnesss. Store Diagnostic ACE in dry,

secure location in shop, not on machine.

Fault Memory and Retrieval

If the Controller senses a fault on one of the output so-

lenoids, it will flash the machines diagnostic Lamp

(Reel Control lamp or green Diagnostic lamp under con-

sole) and store the fault into the Controllers (ECU)

memory. The fault can then be retrieved and viewed with

the Diagnostic ACE hand held tool or a lap top/PC at

anytime. The Controller will store one (1) fault at a time

and will not store another different fault until the first fault

is cleared.

Retrieving Stored Faults

1.

Rotate ignition key to Off position.

2.

Connect the Hand held Diagnostic Tool to the de-

sired Controller Loopback Connector (use the proper

overlay).

3.

Move the Joystick to the Raise position and hold.

4.

Rotate ignition key to On position, and continue to

hold the Joystick in Raise position until the top left Diag-

nostic Tool light comes on (approx. 2 seconds).

5.

Release the Joystick to the center position.

6.

Hand held Tool will now playback the fault retained

in the Controller memory.

IMPORTANT: The display will show eight (8) individual

records with the fault displayed on the 8th record. Each

record will be displayed for 10 seconds. Be sure to have

the

Diagnostic Tool display on Outputs to see fault.

The Problem circuit will be flashing. Records will repeat

until key is turned off. Unit will not start in this mode.

Clearing the Fault Memory

(Diagnostic Tool not required)

1.

Rotate ignition key to Off position.

2.

Turn Backlap Switch to the Front or Rear Backlap

position.

3.

Turn the Reel Control Switch to Enable position.

4.

Move the Joystick to the Raise position and hold.

5.

Turn the ignition key to On, and continue to hold the

Joystick in the Raise position until the Reel Control

Lamp starts to flash (approx. 2 seconds).

6.

Release the Joystick and turn the Key Off. Memory

is now cleared.

7.

Turn the Backlap Switch to Off and Enable Switch to

Disable position.

Summary of Contents for REELMASTER 6500 D

Page 2: ...Reelmaster 6500 D 6700 D ...

Page 4: ...Reelmaster 6500 D 6700 D ...

Page 10: ...Reelmaster 6500 D 6700 D Page 1 6 Safety ...

Page 12: ...Reelmaster 6500 D 6700 D Page 2 2 Product Records and Manuals Equivalents and Conversions ...

Page 20: ...Rev C Reelmaster 6500 D 6700 D Page 2 10 Product Records and Manuals ...

Page 24: ...Rev C Reelmaster 6500 D 6700 D Page 2 14 Product Records and Manuals ...

Page 86: ...Engine Page 3 62 Reelmaster 6500 D 6700 D ...

Page 202: ...Reelmaster 6500 D 6700 D Page 5 8 2 Electrical System Rev C This page is intentionally blank ...

Page 226: ...Reelmaster 6500 D 6700 D Page 5 26 6 Electrical System Rev B This page is blank ...

Page 276: ...Reelmaster 6500 D 6700 D Page 6 22 Axles Planetaries and Brakes ...

Page 300: ...Reelmaster 6500 D 6700 D Page 7 24 Cutting Units Rev B Model 03853 Model 03854 Model 03855 ...