Rev. B

Reelmaster 6500–D/6700–D

Page 5 – 48

Electrical System

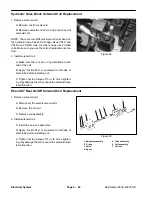

#6 and #7 Reel On/Off Solenoids

1. Disconnect the wire connector.

2. Connect a 12 volt battery so the positive (+) battery

terminal is connected to colored solenoid lead. Connect

the negative (–) battery terminal to black lead. The valve

spool should retract completely as 12 V.D.C. is applied

between leads.

3. If valve spool does not operate properly check for

binding or damage to valve.

4. If valve moves smoothly, but does not engage when

12 V.D.C. is applied to solenoid leads, replace solenoid

coil.

5. If valve still does not operate after replacing solenoid

coil, replace the valve.

Solenoid coil resistance:

3.5 Ohms (+ 10%) at 77

_

F (25

_

C)

3

1

2

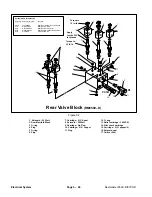

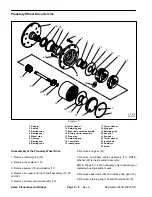

Figure 34

(Located on frame rails)

1. #6 reel solenoid (S10)

2. #7 reel solenoid (S11)

3. Rear valve block

Height of Cut Selector (Potentiometer)

The HOC selector can be tested with the Diagnostic

ACE Display tool.

1. Make sure key switch is OFF.

2. Connect Diagnostic ACE Display tool to controller

loop–back connector – primary controller on

RM6700–D. (See Troubleshooting section for more

information.)

3. Remove overlay decal from Diagnostic ACE Display

tool so numbers 0 to 17 next to lamps are visible.

4. Raise seat and set Backlap switch to FRONT backlap

position.

5. Set Enable/Disable switch to DISABLE position.

6. Hold Lower/Mow–Raise lever in RAISE position and

turn ignition key switch to ON. Release Lower/Mow–

Raise lever.

8. Slowly turn HOC selector. LED’s on Diagnostic ACE

Display tool will show how ECU is interpreting HOC

selector. LED labeled “0” should be illuminated when

knob is pointed to “A”, and LED labeled “15” should be

illuminated when knob is pointed to “P”. It is not neces-

sary for knob to line up with letters on decal for machine

to function normally.

9. Turn key switch OFF and disconnect Diagnostic ACE

Display tool. Connect loop–back connector.

NOTE: The HOC selection potentiometer is factory cali-

brated. If the HOC selection potentiometer must be re-

placed for any reason, the new potentiometer will need

to be calibrated in order to assure the correct clip is deliv-

ered. If the potentiometer is not calibrated correctly, the

delivered clip may be as much as 2 or 3 settings different

from the desired setting. This calibration must be done

by your Toro distributor.

Figure 34a

1. H.O.C. Selector Knob

1

Summary of Contents for REELMASTER 6500 D

Page 2: ...Reelmaster 6500 D 6700 D ...

Page 4: ...Reelmaster 6500 D 6700 D ...

Page 10: ...Reelmaster 6500 D 6700 D Page 1 6 Safety ...

Page 12: ...Reelmaster 6500 D 6700 D Page 2 2 Product Records and Manuals Equivalents and Conversions ...

Page 20: ...Rev C Reelmaster 6500 D 6700 D Page 2 10 Product Records and Manuals ...

Page 24: ...Rev C Reelmaster 6500 D 6700 D Page 2 14 Product Records and Manuals ...

Page 86: ...Engine Page 3 62 Reelmaster 6500 D 6700 D ...

Page 202: ...Reelmaster 6500 D 6700 D Page 5 8 2 Electrical System Rev C This page is intentionally blank ...

Page 226: ...Reelmaster 6500 D 6700 D Page 5 26 6 Electrical System Rev B This page is blank ...

Page 276: ...Reelmaster 6500 D 6700 D Page 6 22 Axles Planetaries and Brakes ...

Page 300: ...Reelmaster 6500 D 6700 D Page 7 24 Cutting Units Rev B Model 03853 Model 03854 Model 03855 ...