Reelmaster 6500–D/6700–D

Page 7 – 22

Cutting Units

Rev. B

Model 03853

Model 03854

Model 03855

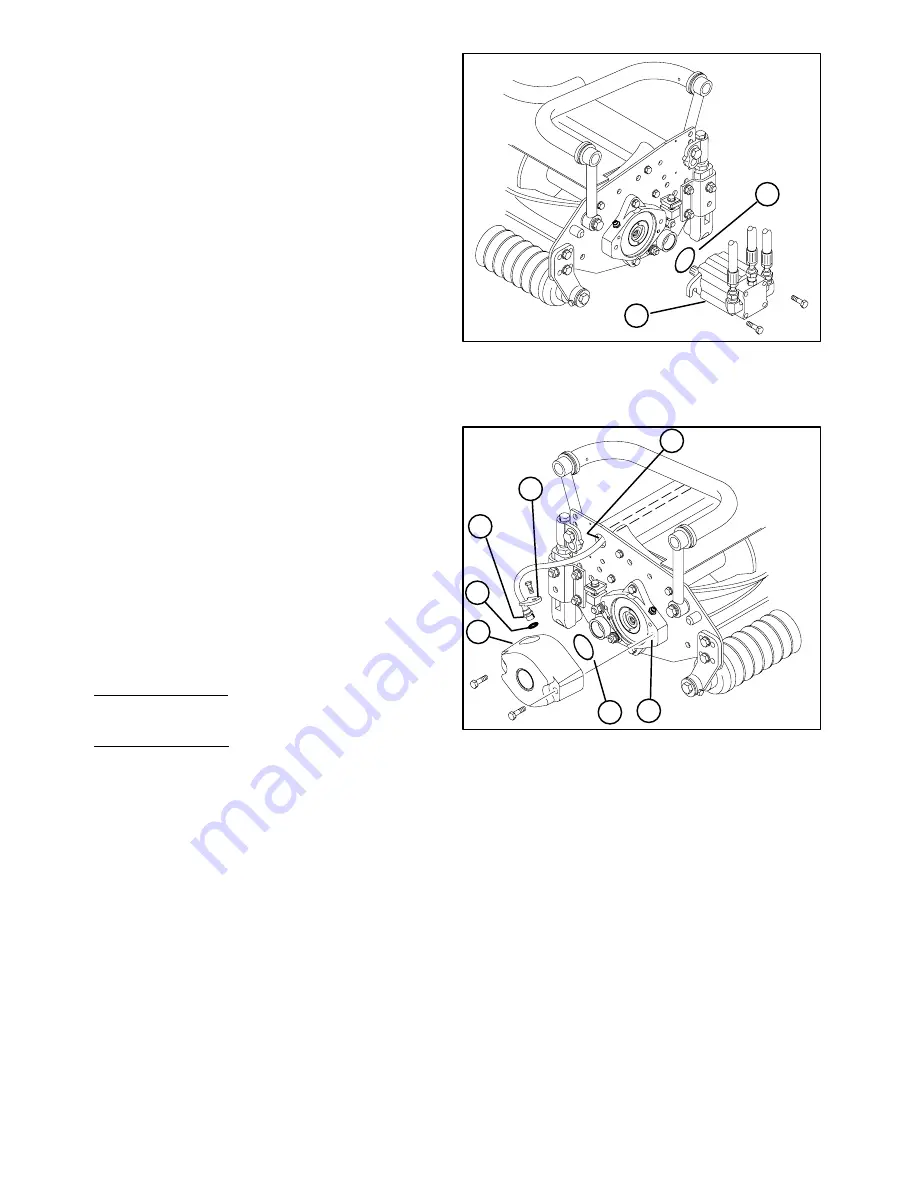

7. Mount the motor to the drive end of the cutting unit and

secure with two capscrews provided (Fig. 30).

8. On front center and left rear cutting units, plug speed

sensor wire harness connector into traction unit wire

harness connector.

9. On motor side of cutting unit, insert speed sensor end

of harness into frame tube and route to counterweight.

10. Install small O–ring onto speed sensor and insert

sensor into hole in counterweight.

11. Secure sensor to counterweight with a sensor holder

and a M6 x 20 mm capscrew.

12. Insert steering pin into either front or rear mounting

hole on pivot knuckle, using one of the following loca-

tions (Fig. 15):

Rear Mounting Hole–Keeps cutting unit in straight

line.

Front Mounting Hole–Allows cutting unit to steer it-

self as traction unit turns.

13. Hook wire around bottom of pin.

Figure 30

1. Motor

2. O–ring

1

1

Figure 31

1. Bearing housing

2. O–ring–large

3. Counterweight

4. O–ring –small

5. Speed sensor

6. Speed sensor holder

7. Frame tube

1

2

4

5

6

7

3

Summary of Contents for REELMASTER 6500 D

Page 2: ...Reelmaster 6500 D 6700 D ...

Page 4: ...Reelmaster 6500 D 6700 D ...

Page 10: ...Reelmaster 6500 D 6700 D Page 1 6 Safety ...

Page 12: ...Reelmaster 6500 D 6700 D Page 2 2 Product Records and Manuals Equivalents and Conversions ...

Page 20: ...Rev C Reelmaster 6500 D 6700 D Page 2 10 Product Records and Manuals ...

Page 24: ...Rev C Reelmaster 6500 D 6700 D Page 2 14 Product Records and Manuals ...

Page 86: ...Engine Page 3 62 Reelmaster 6500 D 6700 D ...

Page 202: ...Reelmaster 6500 D 6700 D Page 5 8 2 Electrical System Rev C This page is intentionally blank ...

Page 226: ...Reelmaster 6500 D 6700 D Page 5 26 6 Electrical System Rev B This page is blank ...

Page 276: ...Reelmaster 6500 D 6700 D Page 6 22 Axles Planetaries and Brakes ...

Page 300: ...Reelmaster 6500 D 6700 D Page 7 24 Cutting Units Rev B Model 03853 Model 03854 Model 03855 ...