Reelmaster 6500–D/6700–D

Page 7 – 23

Cutting Units

Rev. B

Model 03853

Model 03854

Model 03855

Greasing Bearings, Bushings and Pivot Points

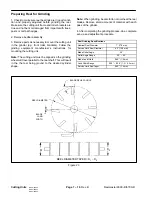

Each cutting unit has (6) grease fittings (Fig. 32) that

must be lubricated regularly with No. 2 General Purpose

Lithium Base Grease.

The grease fitting locations and quantities are: reel

bearings (2) and front and rear rollers (2 ea.)

IMPORTANT: Lubricating cutting units immediately

after washing helps purge water out of bearings and

increases bearing life.

1. Wipe each grease fitting with a clean rag.

2. Apply grease until pressure is felt against handle.

IMPORTANT: Do not apply too much pressure or

grease seals will be permanently damaged.

3. Wipe excess grease away.

Figure 32

Cutting Units

Summary of Contents for REELMASTER 6500 D

Page 2: ...Reelmaster 6500 D 6700 D ...

Page 4: ...Reelmaster 6500 D 6700 D ...

Page 10: ...Reelmaster 6500 D 6700 D Page 1 6 Safety ...

Page 12: ...Reelmaster 6500 D 6700 D Page 2 2 Product Records and Manuals Equivalents and Conversions ...

Page 20: ...Rev C Reelmaster 6500 D 6700 D Page 2 10 Product Records and Manuals ...

Page 24: ...Rev C Reelmaster 6500 D 6700 D Page 2 14 Product Records and Manuals ...

Page 86: ...Engine Page 3 62 Reelmaster 6500 D 6700 D ...

Page 202: ...Reelmaster 6500 D 6700 D Page 5 8 2 Electrical System Rev C This page is intentionally blank ...

Page 226: ...Reelmaster 6500 D 6700 D Page 5 26 6 Electrical System Rev B This page is blank ...

Page 276: ...Reelmaster 6500 D 6700 D Page 6 22 Axles Planetaries and Brakes ...

Page 300: ...Reelmaster 6500 D 6700 D Page 7 24 Cutting Units Rev B Model 03853 Model 03854 Model 03855 ...