Reelmaster 6500–D/6700–D

Page 8 – 20

Cutting Units

Rev. B

Model 03857, S/N 80001–80301

Model 03858, S/N 80001–81418

Model 03859, S/N 80001–81992

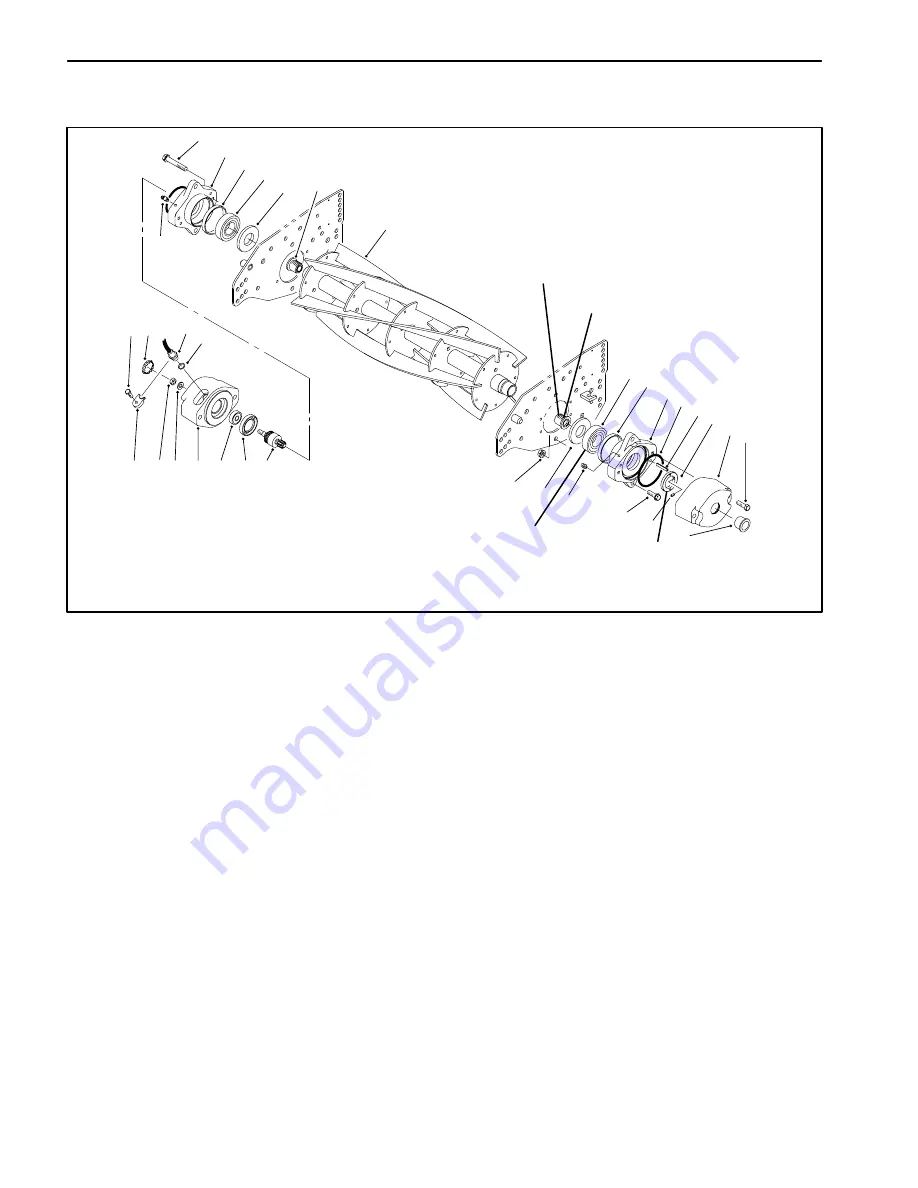

Reel Removal and Bearing Replacement

1

2

3

4

4

6

3

5

8

7

12

11

9 10

28

15

16

13

14

15

17

18

19

20

21

22

23

24

25

26

27

27

29

Use tool TOR4064

Tighten set–screw

Pack bearings with No. 2

general purpose grease

Apply anti–sieze

lubricant to splines

Use tool TOR4074

to install threaded spline insert.

Apply Locite 242 to threads

Tighten to 75 – 85 ft–lb (10.4 – 11.8 KgM)

one–half turn beyond initial

contact minimum

Figure 27

1. Screw

11. End weight

21. Flat washer

2. R.H. bearing housing

12. Screw

22. Lock nut

3. Bearing

13. Cap plug

23. Clamp

4. Grease seal

14. Screw

24. Screw

5. Threaded insert

15. Grease fitting

25. Speed sensor

6. Reel assembly

16. Lock nut

26. O–ring

7. L.H. Bearing housing

17. Shaft magnet assembly

27. Bearing ring

8. O–ring

18. Outer seal

28. Plug

9. Roll pin

19. Bearing

29. Set screw

10. Bearing adjustment nut

20. End weight housing

Summary of Contents for REELMASTER 6500 D

Page 2: ...Reelmaster 6500 D 6700 D ...

Page 4: ...Reelmaster 6500 D 6700 D ...

Page 10: ...Reelmaster 6500 D 6700 D Page 1 6 Safety ...

Page 12: ...Reelmaster 6500 D 6700 D Page 2 2 Product Records and Manuals Equivalents and Conversions ...

Page 20: ...Rev C Reelmaster 6500 D 6700 D Page 2 10 Product Records and Manuals ...

Page 24: ...Rev C Reelmaster 6500 D 6700 D Page 2 14 Product Records and Manuals ...

Page 86: ...Engine Page 3 62 Reelmaster 6500 D 6700 D ...

Page 202: ...Reelmaster 6500 D 6700 D Page 5 8 2 Electrical System Rev C This page is intentionally blank ...

Page 226: ...Reelmaster 6500 D 6700 D Page 5 26 6 Electrical System Rev B This page is blank ...

Page 276: ...Reelmaster 6500 D 6700 D Page 6 22 Axles Planetaries and Brakes ...

Page 300: ...Reelmaster 6500 D 6700 D Page 7 24 Cutting Units Rev B Model 03853 Model 03854 Model 03855 ...