Reelmaster 7000

Hydraulic System

Page 4 -- 93

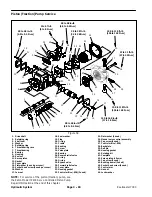

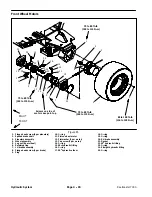

Cutting Reel Motor

The hydraulic reel motors used on all cutting units are

the same.

Removal

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

3. To prevent contamination of hydraulic system during

reel motor removal, thoroughly clean exterior of motor.

4. Disconnect hydraulic hoses from reel motor. Put

caps or plugs on fittings and hoses to prevent contami-

nation of hydraulic system. Label hydraulic hoses for

proper assembly.

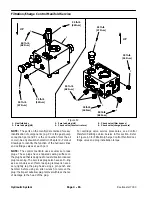

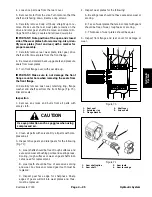

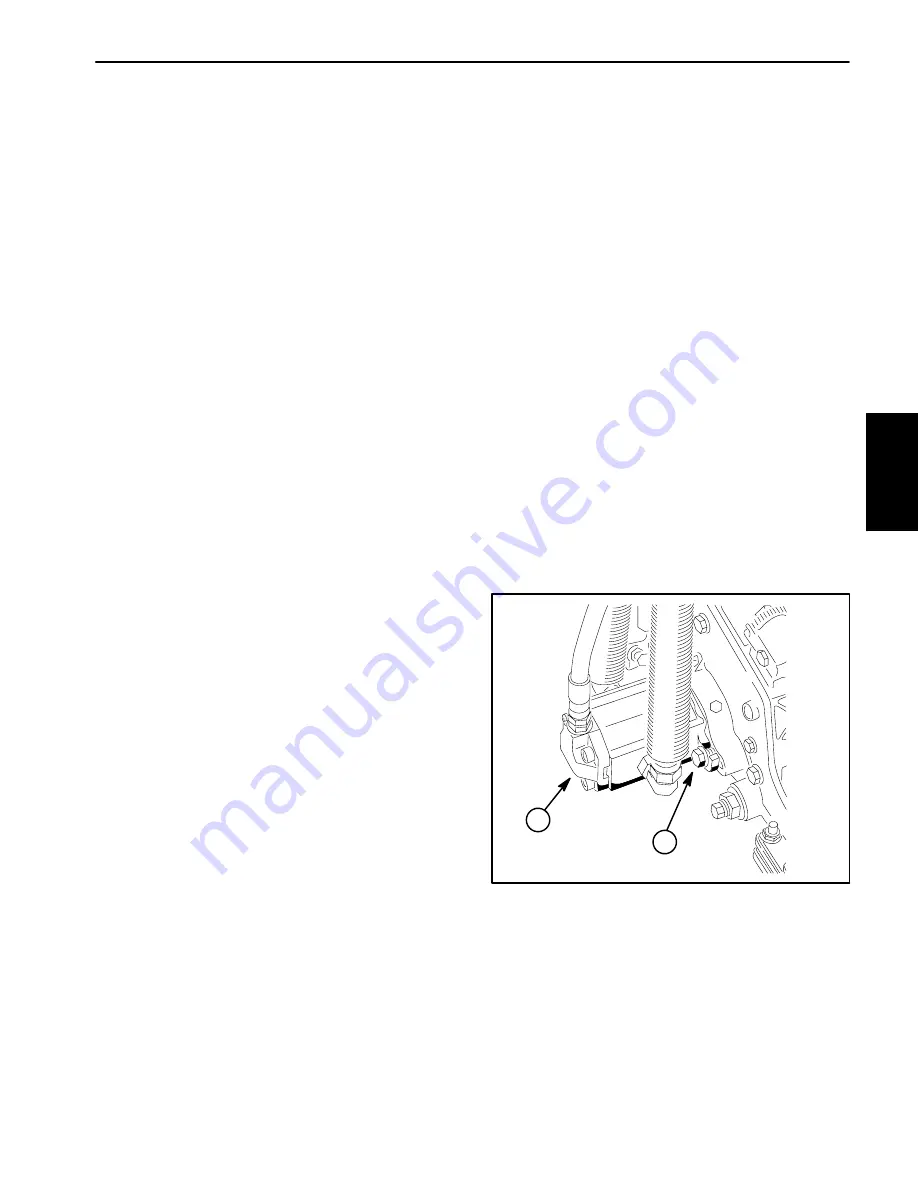

5. Loosen two (2) cap screws that secure the hydraulic

reel motor to the cutting unit side plate. Rotate motor

clockwise and remove motor from cutting unit.

6. Inspect reel insert splines for wear. Replace if neces-

sary (see Reel Removal and Installation in the Service

and Repairs section of Chapter 7 -- DPA Cutting Units).

7. Place protective plastic cap (see Special Tools in this

chapter) into the hole in the cutting unit side plate to pre-

vent debris entry into reel bearing area.

8. If hydraulic fittings are to be removed from reel mo-

tor, mark fitting orientation to allow correct assembly.

Remove fittings from motor and discard O--rings.

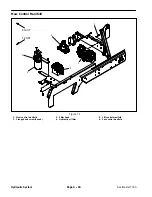

Installation

1. If fittings were removed from reel motor, lubricate

and place new O--rings onto fittings. Install fittings into

motor ports using marks made during the removal pro-

cess to properly orientate fittings. Tighten fittings (see

Hydraulic Fitting Installation in the General Information

section of this chapter).

2. Remove cover from cutting unit opening.

3. Coat spline shaft of the reel motor with No. 2 multi-

purpose lithium base grease.

4. Install the cap screws for the reel drive motor into the

cutting unit side plate and leave approximately 1/2 inch

(12.7 mm) of threads exposed on each screw.

5. Rotate the motor clockwise so the motor flanges

clear the cap screws in the cutting unit side plates. Align

reel motor shaft splines with cutting reel insert splines.

Slide motor shaft into reel insert.

6. Rotate the motor counter--clockwise until the motor

flanges are encircling the cap screws. Tighten two (2)

cap screws to secure reel motor to cutting unit.

7. Remove caps or plugs from hydraulic fittings and

hoses. Connect hydraulic hoses to reel motor (see Hy-

draulic Hose and Tube Installation in the General Infor-

mation section of this chapter).

8. After assembly is completed, verify that hydraulic

hoses and fittings are not contacted by any moving com-

ponents.

9. Check oil level in hydraulic reservoir and add correct

oil if necessary.

10.Follow Hydraulic System Start--up procedures (see

Hydraulic System Start--up in this section).

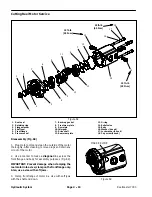

1. Cap screw

2. Hydraulic reel motor

Figure 67

1

2

Hydraulic System

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...