Reelmaster 7000

Page 6 -- 8

Axles, Planetaries and Brakes

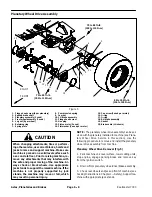

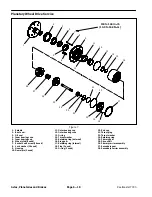

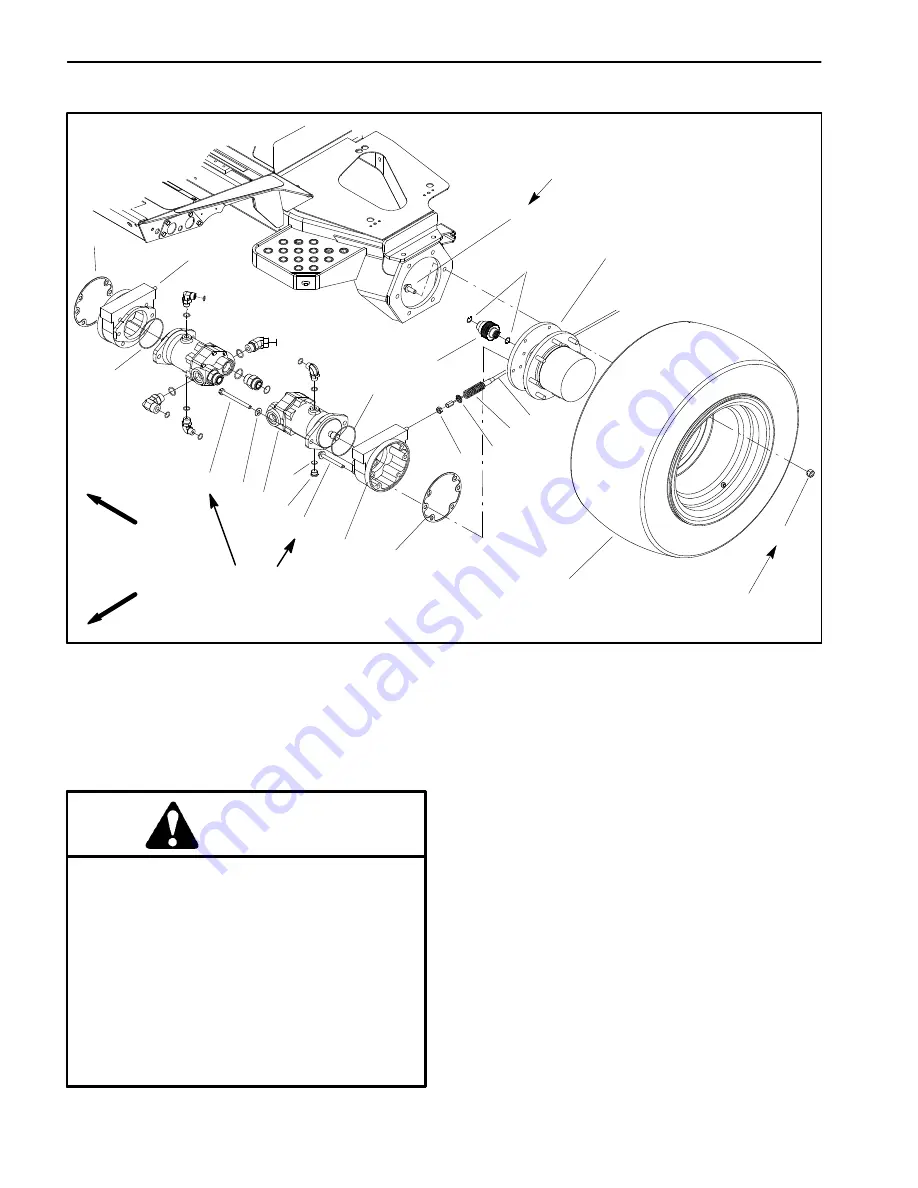

Planetary Wheel Drive Assembly

1. Flange head screw (6 per planetary)

2. Splined brake shaft

3. Planetary assembly (2 used)

4. Front wheel assembly (2 used)

5. Lug nut (8 per wheel)

6. Retaining ring

7. Spring plate

8. Compression spring

9. Jam nut

10. LH Brake assembly

11. Flange head screw

12. Hex plug

13. Piston motor (2 used)

14. Flat washer (2 used per motor)

15. Cap screw (2 used per motor)

16. O--ring

17. O--ring

18. RH brake assembly

19. Gasket

20. Brake cable (LH shown)

Figure 5

75 to 85 ft--lb

(102 to 115 N--m)

85 to 100 ft--lb

(116 to 135 N--m)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

17

18

16

17

75 to 85 ft--lb

(102 to 115 N--m)

FRONT

RIGHT

19

19

20

CAUTION

When changing attachments, tires or perform-

ing other service, use correct blocks, hoists and

jacks to raise and support machine. Make sure

machine is parked on a solid level surface such

as a concrete floor. Prior to raising machine, re-

move any attachments that may interfere with

the safe and proper raising of the machine. Al-

ways chock or block wheels. Use appropriate

jack stands to support the raised machine. If the

machine is not properly supported by jack

stands, the machine may move or fall, which

may result in personal injury.

NOTE:

The planetary wheel drive assembly can be ser-

viced with the planetary installed to machine (see Plane-

tary Wheel Drive Service in this section). Use the

following procedure to remove and install the planetary

wheel drive assembly from machine.

Planetary Wheel Drive Removal (Fig. 5)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Drain oil from planetary wheel drive/brake assembly.

3. Chock rear wheels and jack up front of machine (see

Jacking Instructions in Chapter 1 -- Safety). Support ma-

chine with appropriate jack stands.

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...