Reelmaster 7000

Page 6 -- 9

Axles, Planetaries and Brakes

4. Remove front wheel assembly.

5. Remove hydraulic wheel motor (see Front Wheel

Motor Removal in the Service and Repairs section of

Chapter 4 -- Hydraulic System).

6. Remove brake assembly (see Brake Assembly Re-

moval in this section).

7. Support planetary assembly to prevent it from falling.

Loosen and remove six (6) flange head screws that se-

cure planetary assembly to frame. Remove planetary

assembly from machine.

8. Remove and discard gasket (item 19). Make sure

that all gasket material is removed from both brake and

planetary assemblies.

Planetary Wheel Drive Installation (Fig. 5)

1. Position planetary assembly to machine. Install

flange head screws that secure planetary assembly.

Torque screws from

75 to 85 ft--lb (102 to 115 N--m)

.

2. Apply Loctite Gasket Sealant #2 (or equivalent) to

sealing surfaces of new gasket (item 19). Apply gasket

to brake assembly.

3. Install brake assembly to planetary (see Brake As-

sembly Installation in this section).

4. Install hydraulic wheel motor (see Front Wheel Motor

Installation in the Service and Repairs section of Chap-

ter 4 -- Hydraulic System).

Failure to maintain proper wheel lug nut torque

could result in failure or loss of wheel and may

result in personal injury.

WARNING

5. Install wheel assembly.

6. Lower machine to ground. Torque lug nuts from

85

to 100 ft--lb (116 to 135 N--m)

.

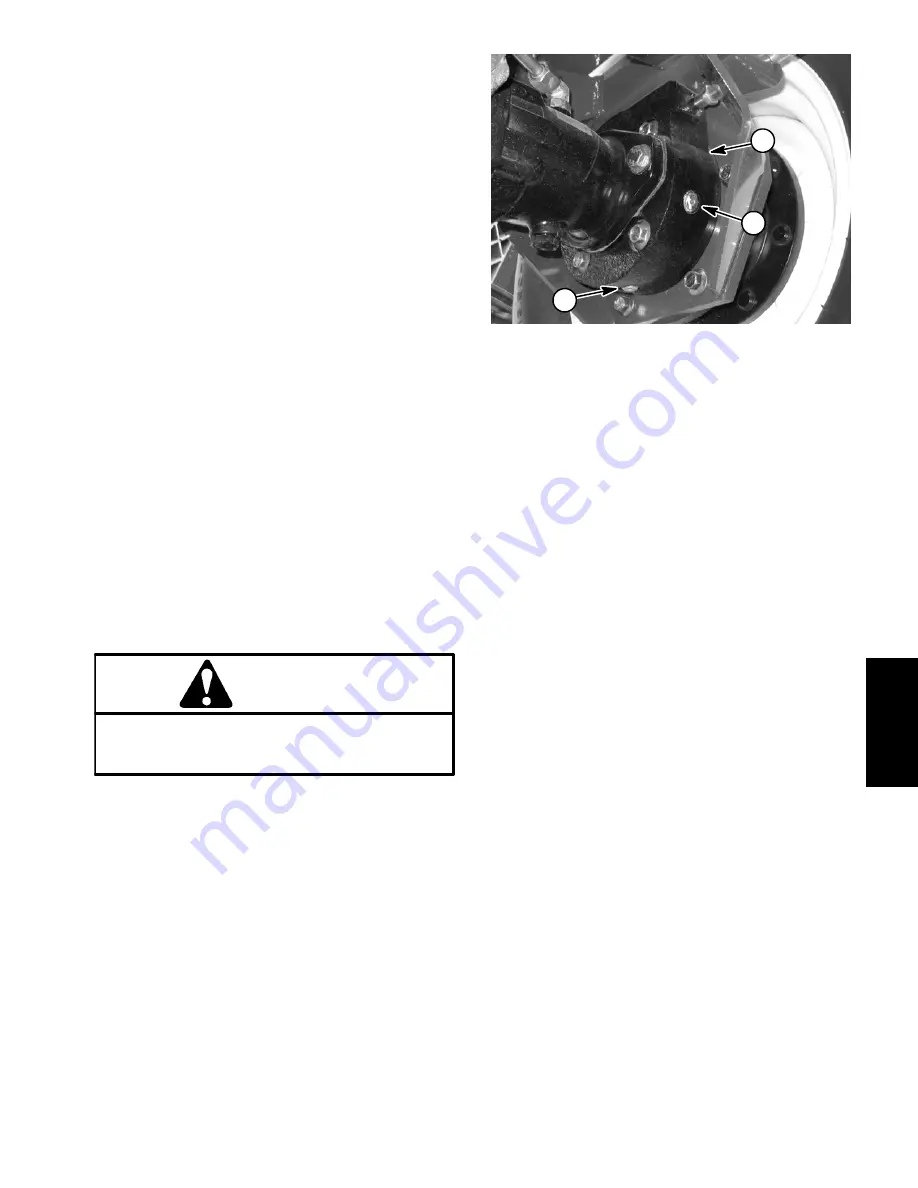

7. Make sure drain plug is installed in bottom of brake

assembly (Fig. 6). Fill planetary wheel drive/brake as-

sembly with SAE 85W--140 gear lube. Capacity is

approximately 16 oz. (0.47 l) per wheel.

8. Check for proper brake operation and adjust brake

cables if necessary.

1. Brake housing

2. Check plug

3. Drain plug

Figure 6

2

1

3

Axles,

Plan

etaries

an

d

B

rakes

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...