Reelmaster 7000

Hydraulic System

Page 4 -- 31

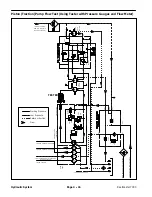

Traction Circuit Problems

NOTE:

When troubleshooting traction circuit problems,

if a problem exists in both mow speed (4WD) and trans-

port speed (2WD), consider a faulty component that af-

fects the entire traction circuit (e.g. charge circuit, relief

valves, piston pump, front wheel motors). If the problem

exists in mow speed (4WD) but not in transport speed

(2WD), consider a problem in the 4WD traction system

(e.g. rear axle motor, cartridge valves in 4WD/2WD con-

trol manifold).

Problem

Possible Cause

Machine operates in one direction

only.

Traction control linkage is faulty.

Traction relief valve is defective.

Traction pedal reaction is sluggish

when in either mow speed (4WD) or

transport speed (2WD).

Traction control linkage is stuck or binding.

Charge pressure is low.

Piston (traction) pump servo control valve orifices are plugged or

damaged.

Traction pedal reaction is sluggish

when in mow speed (4WD). Pedal

reaction is normal when in transport

speed (2WD).

PD1 and PD2 pilot directional valve seals in 4WD/2WD control

manifold are leaking or damaged.

Machine travels too far before stop-

ping when the traction pedal is re-

leased.

Traction linkage is out of adjustment.

Charge pressure is low.

Piston (traction) pump servo control valve orifices are plugged or

damaged.

Traction pedal does not return to neutral.

Traction power is lost or machine will

not operate in either direction.

Hydraulic reservoir oil level is low.

Piston pump bypass valve is open or damaged.

Charge pressure is low.

Traction circuit pressure is low.

Front wheel motor couplers are damaged.

If traction is lost in mow speed (4WD) but is normal in transport

speed (2WD), rear axle motor or rear axle motor drive may be faulty.

Mow speed (4WD) will not engage.

Electrical problem exists (see Chapter 5 -- Electrical System).

Solenoid valve SV in 4WD/2WD control manifold is faulty.

Cartridge valve(s) in 4WD/2WD control manifold is (are) faulty.

Mow speed (4WD) will not disen-

gage.

Electrical problem exists (see Chapter 5 -- Electrical System).

Cutting units are fully lowered.

Cartridge valve in 4WD/2WD control manifold is damaged or sticking.

Hydraulic System

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...