5.

Clean the mating surfaces of the cap and the drain

fitting.

6.

Install the cap onto the drain fitting (Figure 43).

Filling the Engine with Oil

1.

Remove the oil-fill cap from the filler neck by pulling

the cap upward (Figure 43).

Note:

Use a funnel with a flexible hose to direct the

engine oil into the engine.

2.

Fill the crankcase with approximately 7.0 L (7.4 US

qt) of the specified engine oil; refer to Servicing the

Engine Oil and Filter (page 38).

3.

Install the oil-fill cap.

4.

Start the engine, run it at idle for about 2 minutes, and

check for oil leaks.

5.

Stop the engine and remove the key.

6.

Wait for 2 or 3 minutes and check the oil level; refer to

steps 2 through 6 in Checking the Engine Oil Level

(page 23).

7.

Install the side panel; refer to Installing the Side Panels

(page 37).

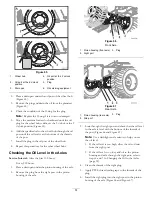

Changing the Engine Oil Filter

Service Interval:

Every 250 hours

1.

Remove the right side panel; refer to Removing the

Side Panels (page 36).

2.

Place a small drain pan under the oil filter and the

oil-filter adapter (Figure 45).

Figure 45

1.

Hydraulic-fluid tank

3.

Oil-filter adapter

2.

Oil filter

3.

Rotate the oil filter counterclockwise and remove the

oil filter (Figure 45).

Note:

Recycle the used oil filter according to local

codes.

4.

Use a clean rag to wipe clean the surface of the oil-filter

adapter, where the oil filter seats.

5.

Fill the new oil filter with the specified engine oil, allow

the filter element to saturate with the oil, and then pour

out the excess oil.

6.

Apply a thin layer of the engine oil to the seal of the

new oil filter.

7.

Align the new oil filter to the oil-filter adapter and

rotate the filter clockwise until the seal of the oil filter

contacts the oil-filter adapter (Figure 45).

Note:

Do not use an oil filter wrench to install the

new oil filter. The wrench can dent an oil filter, causing

a leak.

8.

Hand tighten the oil filter an additional 1/2 turn

(Figure 45).

9.

Remove the small oil pan from under the oil filter.

10.

Install the side panel; refer to Installing the Side Panels

(page 37).

Servicing the Air-cleaner

System

Important:

Do not remove the elements from the

machine to check for a restriction; always follow the

instructions in the following procedures.

Note:

Do not replace an old air cleaner element with an

element that is more than 5 years old; check the date of

manufacture on the end cap of the element.

Note:

Every time you service the air cleaner system, ensure

that all hose connections and flanges are air tight. Replace

all damaged parts.

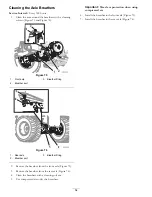

Servicing the Dust Valve

Service Interval:

Every 50 hours

Squeeze the sides of the dust valve to release any collected

water, dust, or dirt from the valve (Figure 46).

Note:

Ensure that there are no obstructions inside the dust

valve.

40

Summary of Contents for RT600

Page 71: ...Notes 71...