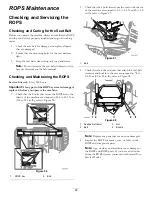

ROPS Maintenance

Checking and Servicing the

ROPS

Checking and Caring for the Seat Belt

Before you operate the machine, always ensure that the ROPS

and the seat belt are properly installed and in good working

order.

1.

Check the seat belt for damage, and replace all parts

that are damaged.

2.

Ensure that the mounting bolts for the seat belts are

tight.

3.

Keep the seat belts clean using only soap and water.

Note:

Do not immerse the seat belts in bleach or dye,

because this weakens the belt material.

Checking and Maintaining the ROPS

Service Interval:

Every 500 hours

Important:

If any part of the ROPS system is damaged,

replace it before you operate the machine.

1.

Check that the 8 bolts that secure the ROPS bar to the

chassis of the machine are torqued to 24.4 to 26.1 N-m

(216 to 231 in-lb); refer to Figure 96.

Figure 96

1.

ROPS bar

2.

Bolt

2.

Check that the 4 bolts that secure the seat to the chassis

of the machine are torqued to 5.4 to 6.8 N-m (48 to 60

in-lb); refer to Figure 97.

Figure 97

1.

Bolt

3.

Check that the bolts and nuts that attach the seat-belt

retractor and buckle to the seat are torqued to 7.8 to

9.6 N-m (69 to 85 in-lb); refer to Figure 98.

Figure 98

1.

Seat-belt retractor

3.

Nut

2.

Bolt

4.

Buckle

Note:

Replace any parts that are worn or damaged.

4.

Inspect the ROPS for cracks, rust, or holes in the

ROPS and component parts.

Note:

Age, weather, and accidents cause damage to

the ROPS and ROPS parts. If you have any doubts

about the ROPS system, contact an Authorized Toro

Service Dealer.

65

Summary of Contents for RT600

Page 71: ...Notes 71...