8. Run the engine until the lift cylinder extends and

retracts and forward and reverse wheel motion is

achieved.

9. Stop the engine and check the oil level in the

reservoir. Add oil if necessary

10. Check all connections for leaks.

11. Lower the seat.

12. Dispose of used oil properly.

Checking the Hydraulic Lines

and Hoses

Service Interval:

Before each use or daily

Check the hydraulic lines and hoses daily for leaks, kinked

lines, loose mounting supports, wear, loose fittings,

weather deterioration, and chemical deterioration. Make

all necessary repairs before operating.

WARNING

Hydraulic fluid escaping under pressure can

penetrate skin and cause injury.

•

Make sure all hydraulic fluid hoses and lines are

in good condition and all hydraulic connections

and fittings are tight before applying pressure to

the hydraulic system.

•

Keep your body and hands away from pin

hole leaks or nozzles that eject high pressure

hydraulic fluid.

•

Use cardboard or paper to find hydraulic leaks.

•

Safely relieve all pressure in the hydraulic system

before performing any work on the hydraulic

system.

•

Seek immediate medical attention if fluid is

injected into skin.

Charging the Hydraulic

System

Whenever a hydraulic component is repaired or

replaced, the hydraulic oil filter should be changed and

the hydraulic system charged.

Make sure that the hydraulic reservoir and filter are filled

with oil at all times when charging the hydraulic system.

1. Park the machine on a level surface and turn the

engine off.

2. Pivot the seat upward and remove the engine shield.

3. Loosen the locknut on the spring adjusting pin until

the bearing moves freely from the cam on the lever

(Figure 30), allowing the pump shaft freedom to

rotate during start-up.

Figure 30

1.

Spring adjusting pin

3.

Cam

2.

Bearing

4. Raise one rear wheel off of the floor and place

support blocks under the frame.

5. Start the engine and set the throttle to allow the

engine to run at approximately 1800 RPM.

6. Actuate the lift valve lever until the lift cylinder

rod moves in and out several times. If the cylinder

rod does not move after 10-15 seconds or the

pump emits abnormal sounds, shut the engine off

immediately and determine the cause or problem.

Inspect for the following:

•

Loose filter or suction lines

•

Loose or faulty coupler on the pump

•

Blocked suction line

•

Faulty charge relief valve

•

Faulty charge pump

If the cylinder moves in 10-15 seconds, proceed to

step 7.

7. Operate the traction pedal in forward and reverse.

The wheel that is off of the floor should rotate in the

proper direction. If the wheel rotates in the wrong

direction, stop the engine, remove the lines from the

rear of the pump and reverse the locations. If the

wheel rotates in the proper direction, stop the engine

and adjust the spring adjusting pin locknut. Adjust

the traction neutral position; refer to Adjusting the

Traction Drive for Neutral.

8. Check the adjustment of the traction interlock

switch; refer to Adjusting the Traction Interlock

Switch.

9. Install the engine shield and lower the seat.

31

Summary of Contents for Sand Pro 2020

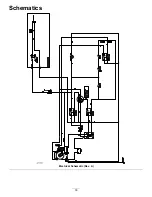

Page 33: ...Schematics Electrical Schematic Rev A 33 ...

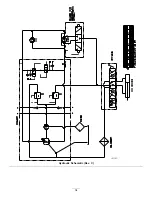

Page 34: ...Hydraulic Schematic Rev C 34 ...

Page 35: ...Notes 35 ...