22

5. Clean around the oil dipstick and unscrew the cap

(Fig. 16).

6. Slowly pour approximately 80% of the specified

amount of oil, page 21, into the filler tube (Fig. 15).

Check the oil level; refer to Checking the Oil Level,

page 21. Slowly add additional oil to bring the level to

the “F” mark on the dipstick.

Changing the Oil Filter

Replace the oil filter every 200 hours or every other oil

change.

Note: Change the oil filter more frequently when operating

conditions are extremely dusty or sandy.

1. Drain the oil from the engine; refer to Changing and

Draining the Oil, page 21.

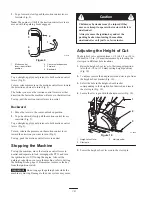

2. Remove the old filter and wipe the filter adapter

(Fig. 17) gasket surface.

3. Place the new filter, open end up, in a shallow pan. Pour

new oil of the proper type in through the center hole.

Stop pouring when the oil reaches the bottom of the

threads. Allow a minute or two for the oil to be

absorbed by the filter material.

4. Apply a thin coat of clean oil to the rubber gasket on the

replacement filter (Fig. 17).

m–1256

1

2

3

Figure 17

1.

Oil filter

2.

Gasket

3.

Adapter

5. Install the replacement oil filter to the filter adapter.

Turn the oil filter clockwise until the rubber gasket

contacts the filter adapter, then tighten the filter an

additional 2/3 to 1 turn (Fig. 17).

6. Fill the crankcase with the proper type of new oil; refer

to Changing and Draining the Oil, page 21.

Cutting Blades

Maintain sharp blades throughout the cutting season

because sharp blades cut cleanly without tearing or

shredding the grass blades. Tearing and shredding turns

grass brown at the edges, which slows growth and increases

the chance of disease.

Check the cutter blades daily for sharpness, and for any

wear or damage. File down any nicks and sharpen the

blades as necessary. If a blade is damaged or worn, replace

it immediately with a genuine Toro replacement blade. For

convenient sharpening and replacement, you may want to

keep extra blades on hand.

Danger

A worn or damaged blade can break, and a piece

of the blade could be thrown into the operator’s or

bystander’s area, resulting in serious personal

injury or death.

•

Inspect the blade periodically for wear or

damage.

•

Replace a worn or damaged blade.

Before Inspecting or Servicing the Blades

Park the machine on a level surface, disengage the PTO,

and set the parking brake. Stop the engine, remove the key,

and disconnect the spark plug wire(s) from the spark

plug(s).

Inspecting the Blades

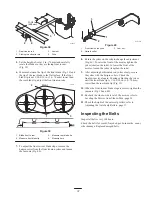

1. Inspect the cutting edges (Fig. 18). If the edges are not

sharp or have nicks, remove and sharpen the blades;

refer to Sharpening the Blades, page 23.

2. Inspect the blades, especially the curved area (Fig. 18).

If you notice any damage, wear, or a slot forming in this

area (item 3 in Fig. 18), immediately install a new

blade.

1

2

3

m–151

Figure 18

1.

Cutting edge

2.

Curved area

3.

Wear/slot forming