Think Safety First

Please read all safety instructions and symbols in the

safety section. Knowing this information could help

you or bystanders avoid injury.

DANGER

Operating the machine on wet grass or steep

slopes can cause sliding and loss of control.

•

Do not operate on slopes greater than 15

degrees.

•

Reduce speed and use extreme caution on

slopes.

•

Do not operate the machine near water.

DANGER

Wheels dropping over edges can cause

rollovers, which may result in serious injury,

death, or drowning.

Do not operate the machine near drop-offs.

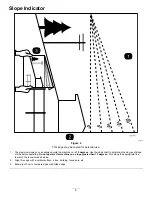

g000513

Figure 9

1.

Safe Zone—use the

machine here on slopes

less than 15 degrees or

flat areas.

3.

Water

2.

Danger Zone—use a

walk-behind mower and/or

a hand trimmer on slopes

greater than 15 degrees

and near drop-offs or

water.

CAUTION

This machine produces sound levels in

excess of 85 dBA at the operator’s ear and

can cause hearing loss through extended

periods of exposure.

Wear hearing protection when operating this

machine.

Use protective equipment for your eyes, ears, hands,

feet, and head.

G009027

1

2

g009027

Figure 10

1.

Wear eye protection.

2.

Wear hearing protection.

Using the Safety-Interlock

System

WARNING

If the safety-interlock switches are

disconnected or damaged, the machine could

operate unexpectedly, causing personal

injury.

•

Do not tamper with the interlock switches.

•

Check the operation of the interlock

switches daily and replace any damaged

switches before operating the machine.

Understanding the

Safety-Interlock System

The safety-interlock system is designed to prevent the

engine from starting unless:

•

The blade-control switch (PTO) is disengaged.

•

The motion-control levers are in the N

EUTRAL

-

LOCK

position.

•

The parking brake is engaged.

The safety-interlock system also is designed to shut

off the engine whenever the control levers are out of

the N

EUTRAL

-

LOCK

position and you rise from the seat.

15