g235264

Figure 41

7.

Dispose of the used oil at a recycling center.

Servicing the Spark Plug

Service Interval:

Every 100 hours/Yearly (whichever

comes first)—Check the spark

plug(s).

Every 200 hours/Every 2 years (whichever

comes first)—Replace the spark plug(s).

Ensure that the air gap between the center and side

electrodes is correct before installing the spark plug.

Use a spark plug wrench for removing and installing

the spark plug and a gapping tool or feeler gauge to

check and adjust the air gap. Install a new spark plug

if necessary.

Type:

Champion

®

RN9YC or NGK

®

BPR6ES

Air gap:

0.76 mm (0.03 inch)

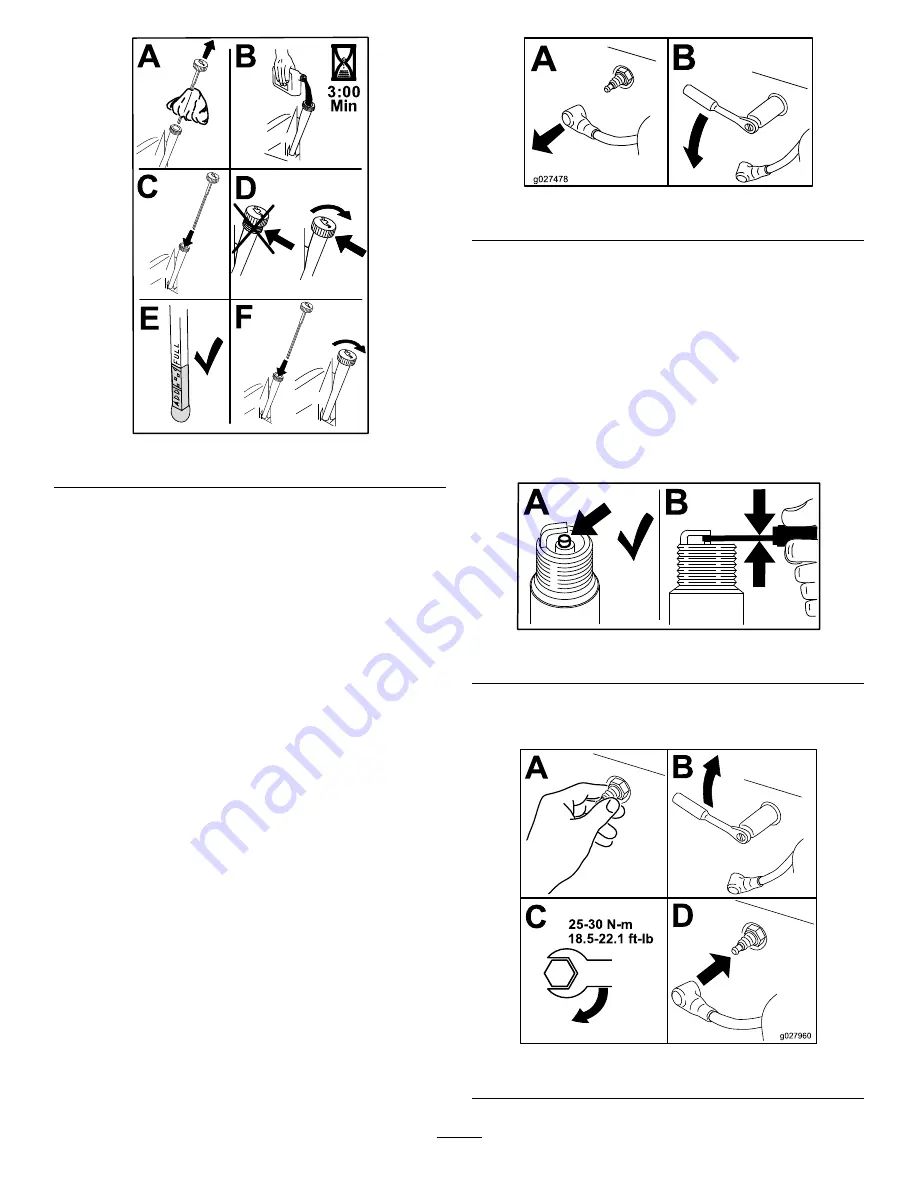

Removing the Spark Plug

1.

Park the machine on a level surface, disengage

the blade-control switch (PTO), and engage the

parking brake.

2.

Shut off the engine, remove the key, and wait

for all moving parts to stop before leaving the

operating position.

3.

Clean the area around the base of the plug to

keep dirt and debris out of the engine.

4.

Remove the spark plug (

).

g027478

Figure 42

Checking the Spark Plug

Important:

Do not clean the spark plug(s).

Always replace the spark plug(s) when it has a

black coating, worn electrodes, an oily film, or

cracks.

If you see light brown or gray on the insulator, the

engine is operating properly. A black coating on the

insulator usually means the air cleaner is dirty.

Set the gap to 0.75 mm (0.03 inch).

g206628

Figure 43

Installing the Spark Plug

g027960

Figure 44

37