Mower Maintenance

Servicing the Cutting Blades

To ensure a superior quality of cut, keep the blades sharp. For

convenient sharpening and replacement, keep extra blades

on hand.

Blade Safety

A worn or damaged blade can break, and a piece of the blade

could be thrown toward you or bystanders, resulting in serious

personal injury or death. Trying to repair a damaged blade

may result in discontinued safety certification of the product.

•

Inspect the blades periodically for wear or damage.

•

Use care when checking the blades. Wrap the blades or

wear gloves, and use caution when servicing the blades.

Only replace or sharpen the blades; never straighten or

weld them.

•

On multi-bladed machines, take care as rotating 1 blade

can cause other blades to rotate.

Before Inspecting or Servicing the

Blades

1.

Park the machine on a level surface, disengage the

blade-control switch (PTO), and engage the parking

brake.

2.

Shut off the engine, remove the key, and disconnect the

spark-plug wires from the spark plugs.

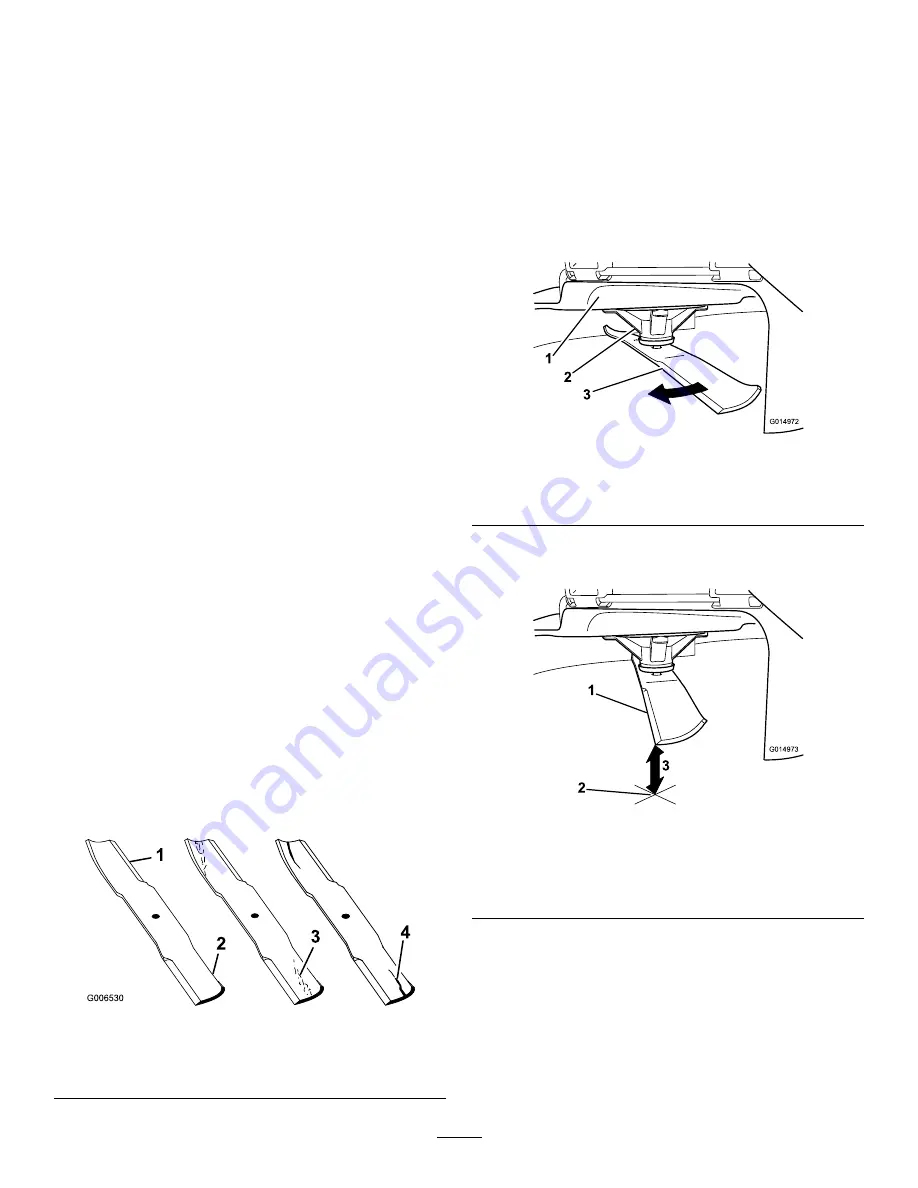

Inspecting the Blades

Service Interval:

Before each use or daily

1.

Inspect the cutting edges (

).

2.

If the edges are not sharp or have nicks, remove and

sharpen the blade; refer to

Sharpening the Blades (page

.

3.

Inspect the blades, especially in the curved area.

4.

If you notice any cracks, wear, or a slot forming in this

area, immediately install a new blade (

).

g006530

Figure 60

1.

Cutting edge

3.

Wear/slot forming

2.

Curved area

4.

Crack

Checking for Bent Blades

Note:

The machine must be on a level surface for the

following procedure.

1.

Raise the mower deck to the highest height-of-cut

position.

2.

While wearing thickly padded gloves, or other adequate

hand protection, slowly rotate the blade to be measure

into a position that allows effective measurement of the

distance between the cutting edge and the level surface

the machine is on (

).

G014972

1

2

3

g014972

Figure 61

1.

Deck

3.

Blade

2.

Spindle housing

3.

Measure from the tip of the blade to the flat surface

(

).

G014973

1

2

3

g014973

Figure 62

1.

Blade (in position for measuring)

2.

Level surface

3.

Measured distance between blade and the surface (A)

4.

Rotate the same blade 180 degrees so that the opposing

cutting edge is now in the same position (

43

Summary of Contents for TimeCutter HD X5450

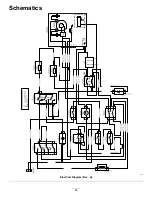

Page 55: ...Schematics g203461 Electrical Diagram Rev A 55 ...

Page 56: ...Notes ...

Page 57: ...Notes ...

Page 58: ...Notes ...