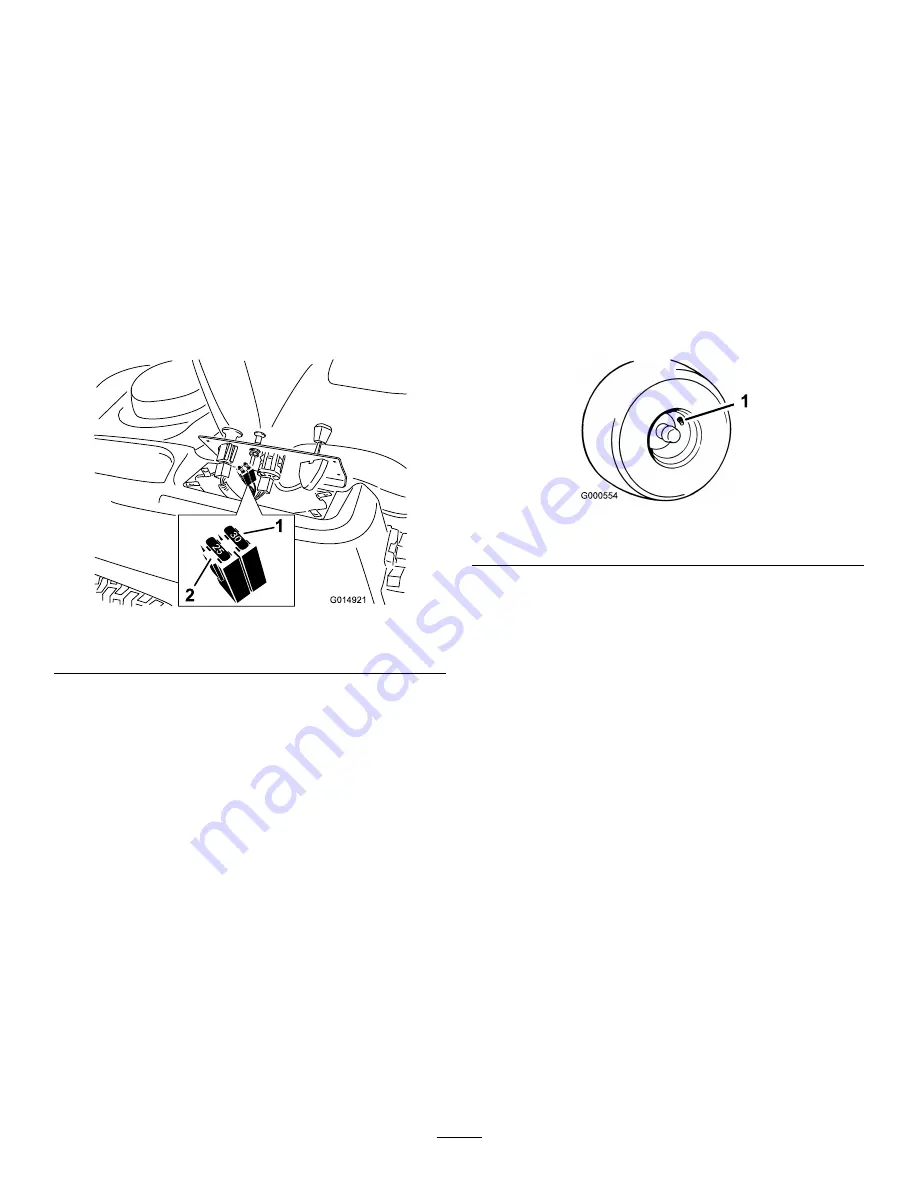

Servicing the Fuses

The electrical system is protected by fuses. It requires

no maintenance; however, if a fuse blows, check the

component/circuit for a malfunction or short.

Fuse:

•

Main F1-30 amp, blade-type

•

Charge Circuit F2-25 amp, blade-type

1.

Remove the screws securing the control panel to the

machine. Retain all fasteners

2.

Lift the control pane up to access the main wiring

harness and fuse block (

).

3.

To replace a fuse, pull out on the fuse to remove it

(

).

30

25

30

25

G014921

2

1

Figure 41

1.

Main—30 amp

2.

Charge circuit—25 amp

4.

Return the control panel to its original position. Use

the screws removed previously to secure the panel to

the machine.

Drive System

Maintenance

Checking the Tire Pressure

Service Interval:

Every 25 hours—Check tire pressure.

Maintain the air pressure in the front and rear tires as

specified. Uneven tire pressure can cause uneven cut. Check

the pressure at the valve stem (

). Check the tires

when they are cold to get the most accurate pressure reading.

Refer to the maximum pressure suggested by the tire

manufacturer on the sidewall of the caster wheel tires.

Inflate the rear drive wheel tires to 89.6 kPa (13 psi).

Figure 42

1.

Valve stem

36

Summary of Contents for TimeCutter SS 5000

Page 49: ...Schematics Electrical Diagram Rev A 49 ...

Page 50: ...Notes 50 ...

Page 51: ...Notes 51 ...