Inspecting the Blades

Service Interval:

Before each use or daily—Check the

cutting blades.

1.

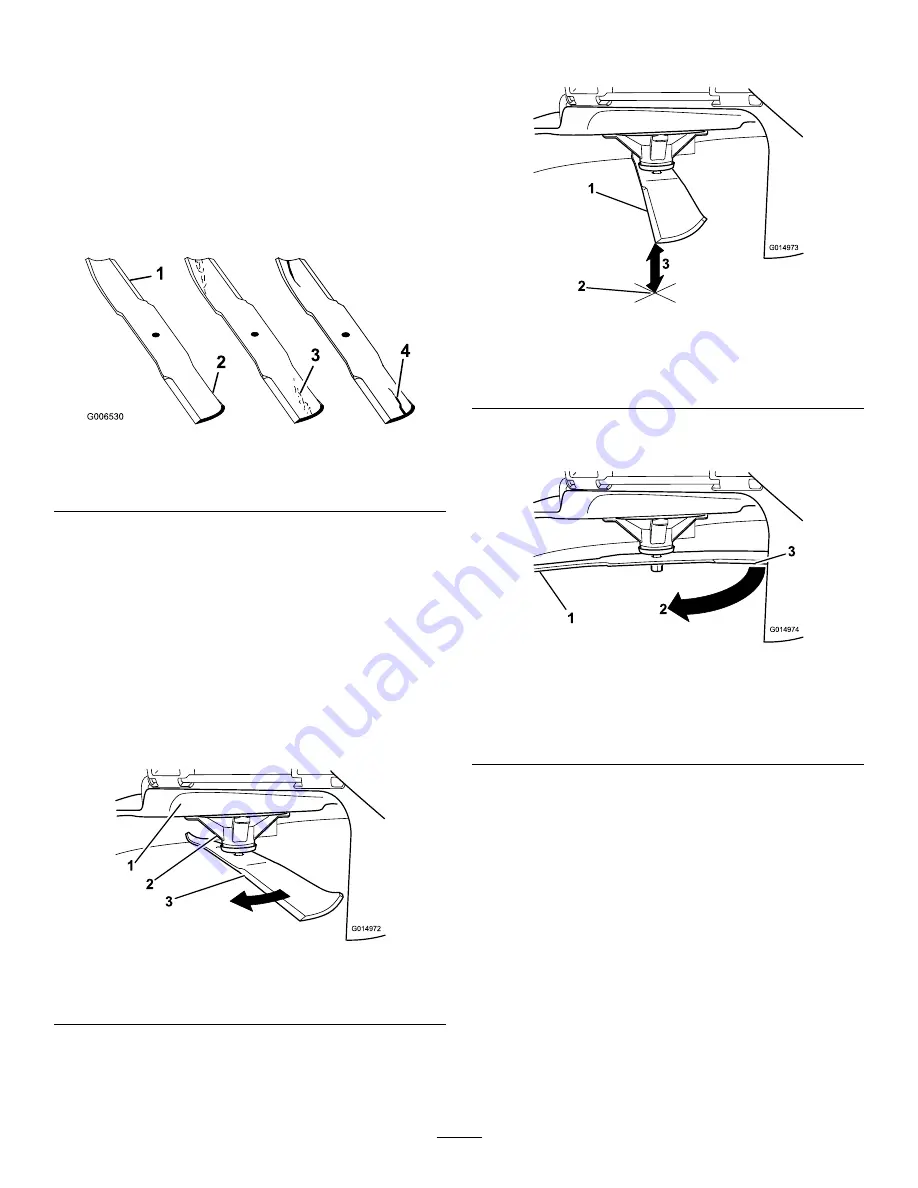

Inspect the cutting edges (

). If the edges

are not sharp or have nicks, remove and sharpen the

blades; refer to

(page )

.

2.

Inspect the blades, especially the curved area (

). If you notice any damage, wear, or a slot forming

in this area (item 3 or 4 in

), immediately

install a new blade.

Figure 44

1.

Cutting edge

3.

Wear/slot forming

2.

Curved area

4.

Damage

Checking for Bent Blades

Note:

The machine must be on a level surface for the

following procedure.

1.

Raise the mower deck to the highest height-of-cut

position; also considered the 'transport' position.

2.

While wearing thickly padded gloves or other adequate

hand protection slowly rotate blade to be measured

into a position that allows effective measurement of the

distance between the cutting edge and the level surface

the machine is on (

).

G014972

1

2

3

Figure 45

1.

Deck

3.

Blade

2.

Spindle housing

3.

Measure from the tip of the blade to the flat surface

(

).

G014973

1

2

3

Figure 46

1.

Blade, in position for measuring

2.

Level surface

3.

Measured distance between blade and surface (A)

4.

Rotate the same blade 180 degrees so that the opposing

cutting edge is now in the same position (

G014974

1

2

3

Figure 47

1.

Blade, side previously measured

2.

Measurement position used previously

3.

Opposing side of blade being moved into measurement

position

38

Summary of Contents for TimeCutter SS 5000

Page 49: ...Schematics Electrical Diagram Rev A 49 ...

Page 50: ...Notes 50 ...

Page 51: ...Notes 51 ...