Electrical System

Maintenance

WARNING

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, and related

accessories contain lead and lead

compounds, chemicals known to

the State of California to cause

cancer and reproductive harm. Wash

hands after handling.

Servicing the Battery

Removing the Battery

WARNING

Battery terminals or metal tools could short

against metal machine components causing

sparks. Sparks can cause the battery gasses

to explode, resulting in personal injury.

•

When removing or installing the battery,

do not allow the battery terminals to touch

any metal parts of the machine.

•

Do not allow metal tools to short between

the battery terminals and metal parts of the

machine.

1.

Park the machine on a level surface and

disengage the blade-control switch.

2.

Ensure that the parking brake is engaged,

shut off the engine, remove the key, and wait

for all moving parts to stop before leaving the

operating position.

3.

Raise the seat to access the battery.

4.

Disconnect the negative (black) ground cable

from the battery post (

). Retain all

fasteners.

WARNING

Incorrect battery cable routing could

damage the machine and cables causing

sparks. Sparks can cause the battery

gasses to explode, resulting in personal

injury.

•

Always disconnect the negative

(black) battery cable before

disconnecting the positive (red)

cable.

•

Always connect the positive (red)

battery cable before connecting the

negative (black) cable.

5.

Slide the rubber cover up the positive (red)

cable. Disconnect the positive (red) cable from

the battery post (

). Retain all fasteners.

6.

Remove the battery hold-down (

) and

lift the battery from the battery tray.

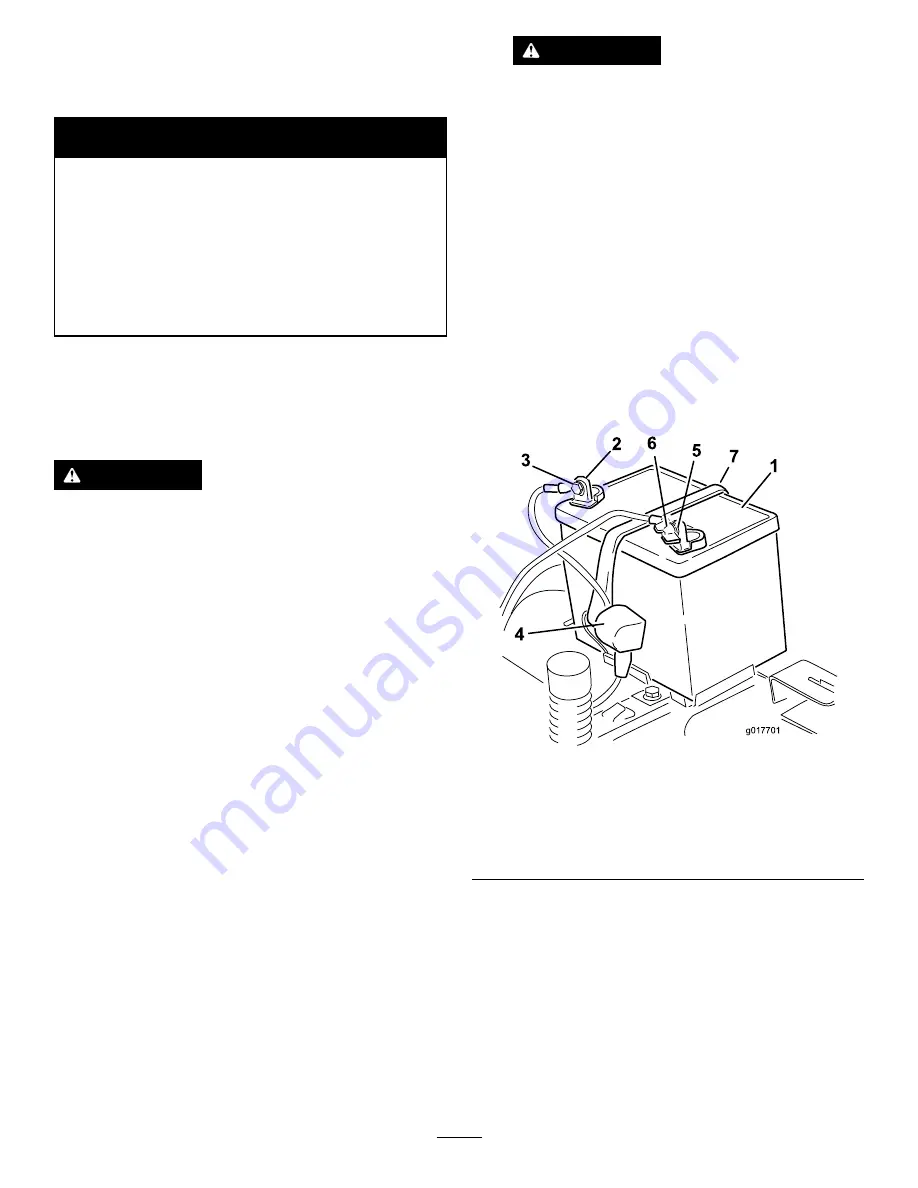

g017701

Figure 37

1.

Battery

5.

Negative battery post

2.

Positive battery post

6.

Wing nut, washer, and bolt

3.

Bolt, washer, and nut

7.

Battery hold-down

4.

Terminal boot

Charging the Battery

Service Interval:

Before storage—Charge the battery

and disconnect battery cables.

1.

Remove the battery from the chassis; refer to

Removing the Battery.

2.

Charge the battery for a minimum of 1 hour at 6

to 10 A. Do not overcharge the battery.

3.

When the battery is fully charged, unplug

the charger from the electrical outlet, then

37

Summary of Contents for TimeCutter SW 5000

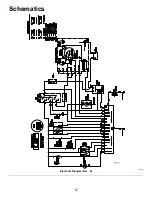

Page 52: ...Schematics g027754 Electrical Diagram Rev A 52 ...

Page 53: ...Notes ...

Page 54: ...Notes ...

Page 55: ...Notes ...