Note:

Now is the best time to install a new

fuel filter because the fuel tank is empty.

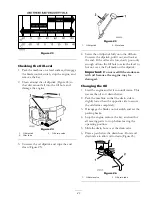

7. Install the fuel line onto the fuel filter. Slide

the hose clamp close to the fuel filter to secure

the fuel line (Figure 31).

Replacing the Fuel Filter

Replace the fuel filter after every 100 operating

hours or yearly, whichever occurs first.

Never install a dirty filter if it is removed from the

fuel line.

1. Park the machine on a level surface and

disengage the blade control switch.

2. Move the motion control levers outward to the

park position, stop the engine, remove the key,

and wait for all moving parts to stop before

leaving the operating position.

3. Close the fuel shut-off valve located under the

front of the fuel tank.

4. Squeeze the ends of the hose clamps together

and slide them away from the filter (Figure 31).

5. Remove the filter from the fuel lines.

6. Install a new filter with the flow direction

arrow coming from the fuel tank and pointing

to the engine and move the hose clamps close

to the filter (Figure 31).

7. Open the fuel shut-off valve.

Electrical System

Maintenance

Servicing the Battery

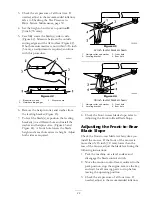

Check the electrolyte level in the battery every

25 hours. Always keep the battery clean and fully

charged. Use a paper towel to clean the battery

case. If the battery terminals are corroded, clean

them with a solution of four parts water and one

part baking soda. Apply a light coating of grease

to the battery terminals to prevent corrosion.

Voltage: 12 V

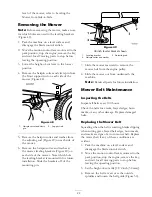

Removing the Battery

Battery terminals or metal tools could short

against metal machine components causing

sparks. Sparks can cause the battery gasses

to explode, resulting in personal injury.

•

When removing or installing the battery,

do not allow the battery terminals to

touch any metal parts of the machine.

•

Do not allow metal tools to short between

the battery terminals and metal parts of

the machine.

1. Park the machine on a level surface and

disengage the blade control switch.

2. Move the motion control levers outward to the

park position, stop the engine, remove the key,

and wait for all moving parts to stop before

leaving the operating position.

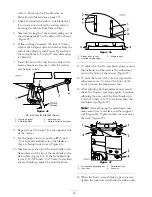

3. Tip the seat forward to see the battery.

4. Disconnect the negative (black) ground cable

from the battery post (Figure 32).

Incorrect battery cable routing could

damage the machine and cables causing

sparks. Sparks can cause the battery

gasses to explode, resulting in personal

injury.

•

Always disconnect the negative

(black) battery cable before

disconnecting the positive (red)

cable.

•

Always connect the positive (red)

battery cable before connecting the

negative (black) cable.

5. Slide the rubber cover up the positive (red)

cable. Disconnect the positive (red) cable from

the battery post (Figure 32).

6. Remove the battery hold-down (Figure 32) and

lift the battery from the battery tray.

28

Summary of Contents for TimeCutter Z380

Page 8: ...Slope Chart 8 ...