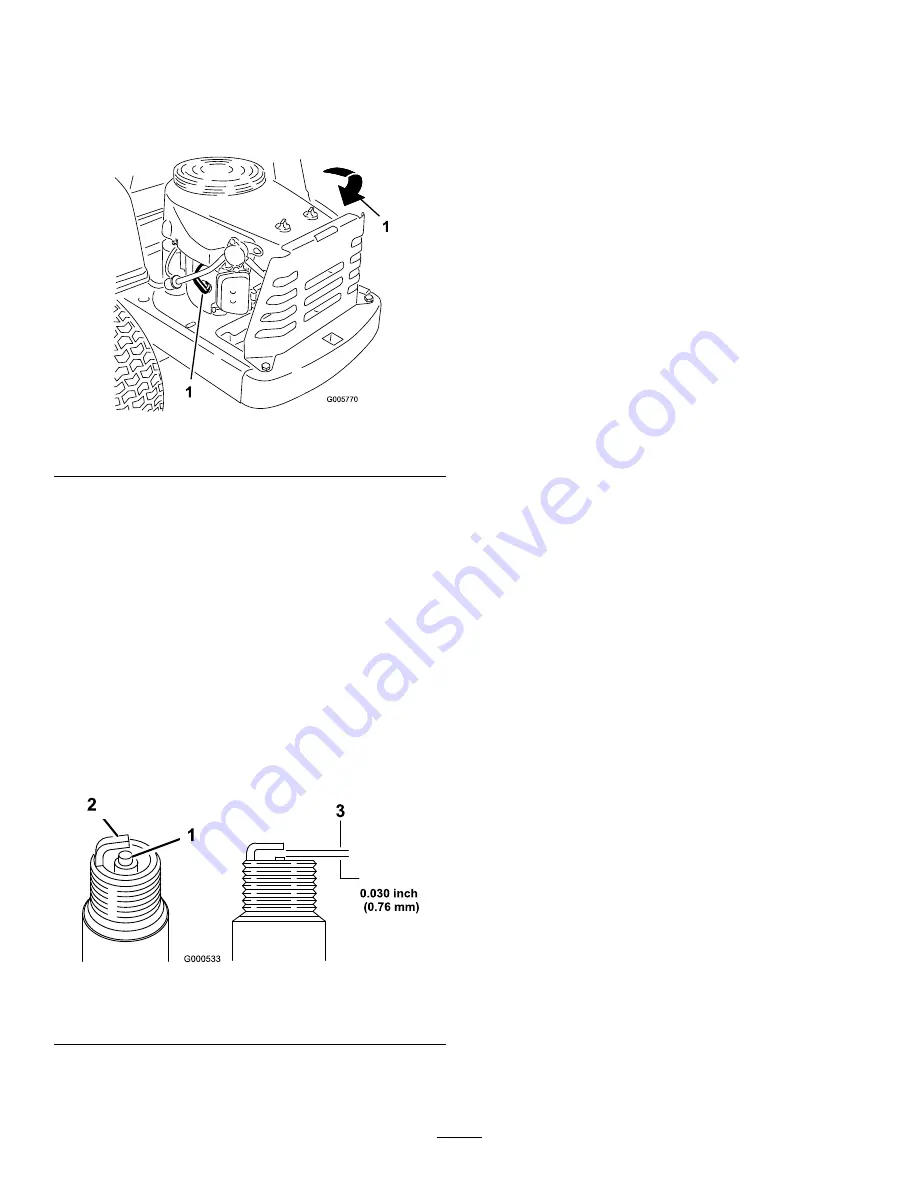

3. Pull the wire(s) off of the spark plug(s) (Figure 28).

Clean around the spark plug(s) to prevent dirt

from falling into the engine and potentially causing

damage.

4. Remove the spark plug(s) and metal washer.

G005770

1

1

Figure 28

1.

Spark plug location

Checking the Spark Plug

1. Look at the center of the spark plug(s) (Figure 29).

If you see light brown or gray on the insulator, the

engine is operating properly. A black coating on the

insulator usually means the air cleaner is dirty.

Important:

Never clean the spark plug(s).

Always replace the spark plug(s) when it has a

black coating, worn electrodes, an oily film, or

cracks.

2. Check the gap between the center and side electrodes

(Figure 29). Bend the side electrode (Figure 29) if

the gap is not correct.

Figure 29

1.

Center electrode insulator

3.

Air gap (not to scale)

2.

Side electrode

Installing the Spark Plug(s)

1. Install the spark plug(s). Make sure that the air gap

is set correctly.

2. Tighten the spark plug(s) to 16 ft-lb (22 N

⋅

m).

3. Push the wire(s) onto the spark plug(s) (Figure 28).

26