Premaintenance

Procedures

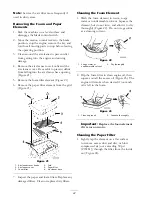

Removing and Installing the

Engine Hood

1. To remove the hood, loosen the knobs and

then pull the hood back and up (Figure 17).

Figure 17

1. Engine hood

2. Knob

2. To install the hood, put the hooks into the

slots and slide forward (Figure 18).

3. Tighten the knobs in the engine hood

Figure 18

1. Engine hood

2. Hook

Lubrication

Greasing the Bearings

Grease the front caster pivots and wheels

(Figure 19).

1. Park the machine on a level surface and

disengage the blade control switch.

2. Move the motion control levers to the brake

position, stop the engine, remove the key, and

wait for all moving parts to stop before leaving

the operating position.

3. Clean the grease fittings (Figure 19 and

Figure 20) with a rag. Make sure to scrape any

paint off of the front of the fitting(s).

Figure 19

1. Front caster tire

Figure 20

4. Connect a grease gun to each fitting (Figure 19

and Figure 20). Pump grease into the fittings

until grease begins to ooze out of the bearings.

5. Wipe up any excess grease.

Engine Maintenance

Servicing the Air Cleaner

Clean the air filter after every 50 operating hours

or every 3 months, whichever occurs first.

Replace the air filter after every 300 operating

hours or yearly, whichever occurs first.

21

Summary of Contents for TimeCutter Z530

Page 41: ...Schematics Electrical Diagram Rev B 41 ...

Page 42: ......

Page 43: ......

Page 44: ......