wait for all moving parts to stop before leaving

the operating position.

3. Remove the engine hood.

4. Clean around the air cleaner to prevent dirt

from getting into the engine and causing

damage. Pull up on the air cleaner cover handle

and rotate it toward the engine (Figure 30).

Remove the air cleaner cover.

Figure 30

1. Air cleaner cover

2. Air cleaner cover handle

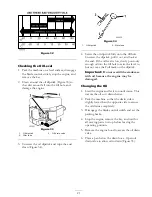

5. Carefully slide the paper element and foam

element from the blower housing (Figure 31).

Figure 31

1. Paper element

4. Tab

2. Foam element

5. Slot

3. Air cleaner cover

6. Blower housing

Cleaning the Foam Element

1. Wash the foam element in liquid soap and

warm water. When the element is clean, rinse

it thoroughly.

2. Dry the element by squeezing it in a clean

cloth. Do not oil the element.

Important:

Replace the foam element

if it is torn or worn.

Important:

Do not clean or oil the paper

element. Replace the paper element if it is

damaged or cannot be cleaned thoroughly.

Installing the Foam and Paper

Elements

Important:

To prevent engine damage,

always operate the engine with the complete

foam and paper air cleaner assembly installed.

1. Place the foam element and paper element into

the blower housing.

Note:

Make sure that the rubber seal is flat

against the air cleaner base.

2. Align the tabs on the air cleaner cover with the

slots of the blower housing (Figure 31). Hook

the handle onto the cover and press down on

the handle to lock the cover in place.

Servicing the Engine Oil

Check the oil level daily or after every 8 hours.

Change the oil after the first 5 operating hours and

every 50 operating hours thereafter.

Oil Type: Detergent oil (API service SG, SH, SJ,

SL or higher)

Crankcase Capacity:

•

48 oz./1-1/2 qt. (1400 cc/1.4 l) when the filter

is not changed;

•

56 oz./1-3/4 qt. (1700 cc/1.7 l) when the filter

is changed (Model 74433 only)

Viscosity: See the table below.

30

Summary of Contents for TimeCutter ZD420

Page 8: ...Slope Chart 8 ...

Page 49: ...Schematics Electrical Diagram Rev A 49 ...

Page 50: ......

Page 51: ......

Page 52: ......