Removing the Battery

Battery terminals or metal tools could short

against metal machine components causing

sparks. Sparks can cause the battery gasses

to explode, resulting in personal injury.

•

When removing or installing the battery,

do not allow the battery terminals to

touch any metal parts of the machine.

•

Do not allow metal tools to short between

the battery terminals and metal parts of

the machine.

1. Park the machine on a level surface and

disengage the blade control switch.

2. Move the motion control levers to the brake

position, stop the engine, remove the key, and

wait for all moving parts to stop before leaving

the operating position.

3. Tip the seat forward to see the battery.

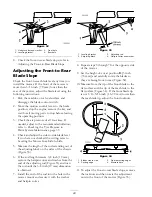

4. Disconnect the negative (black) ground cable

from the battery post (Figure 41).

Incorrect battery cable routing could

damage the machine and cables causing

sparks. Sparks can cause the battery

gasses to explode, resulting in personal

injury.

•

Always disconnect the negative

(black) battery cable before

disconnecting the positive (red)

cable.

•

Always connect the positive (red)

battery cable before connecting the

negative (black) cable.

5. Slide the rubber cover up the positive (red)

cable. Disconnect the positive (red) cable from

the battery post (Figure 41).

6. Remove the battery hold-down (Figure 41) and

lift the battery from the battery tray.

Figure 41

1. Battery

4. Negative battery cable

2. Terminal boot

5. Battery hold-down

3. Positive battery cable

6. Bolt, nut, and washer

Checking the Battery Electrolyte Level

Battery electrolyte contains sulfuric acid

which is a deadly poison and causes severe

burns.

•

Do not drink electrolyte and avoid

contact with skin, eyes or clothing. Wear

safety glasses to shield your eyes and

rubber gloves to protect your hands.

•

Fill the battery where clean water is

always available for flushing the skin.

1. Tip the seat forward to see the battery.

2. Look at the side of the battery. The electrolyte

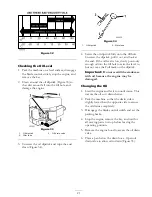

must be up to the Upper line (Figure 42).

Do not allow the electrolyte to fall below the

Lower line (Figure 42).

Figure 42

1. Vent caps

3. Lower line

2. Upper line

3. If the electrolyte is low, add the required amount

of distilled water; refer to Adding Water to

35

Summary of Contents for TimeCutter ZD420

Page 8: ...Slope Chart 8 ...

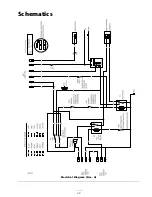

Page 49: ...Schematics Electrical Diagram Rev A 49 ...

Page 50: ......

Page 51: ......

Page 52: ......