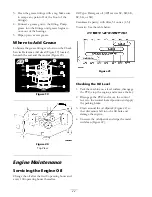

Figure 32

1. Battery

5. Battery hold-down

2. Terminal boot

6. Bolt and washer

3. Positive battery cable

7. Nut

4. Negative battery cable

Installing the Battery

1. Position the battery in the tray with the

terminal posts away from the control panel

(Figure 32).

2. Install the positive (red) battery cable to the

positive (+) battery terminal.

3. Install the negative battery cable to the negative

(-) battery terminal.

4. Secure the cables with 2 bolts (1/4 x 3/4 inch),

washers (1/4 inch), and nuts (1/4 inch)

(Figure 32).

5. Slide the red terminal boot onto the positive

(red) battery post.

6. Secure the battery with the hold-down

(Figure 32).

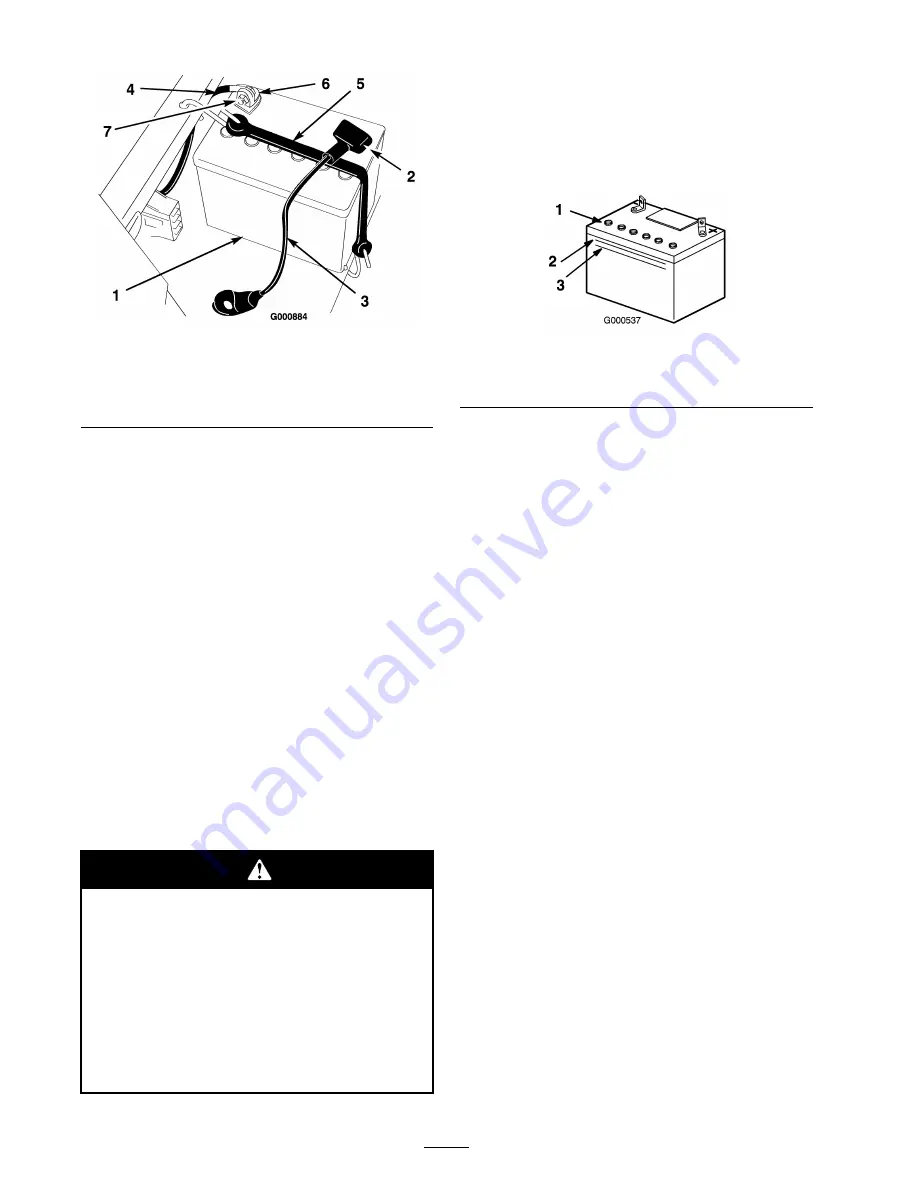

Checking the Electrolyte Level

Battery electrolyte contains sulfuric acid

which is a deadly poison and causes severe

burns.

•

Do not drink electrolyte and avoid

contact with skin, eyes or clothing. Wear

safety glasses to shield your eyes and

rubber gloves to protect your hands.

•

Fill the battery where clean water is

always available for flushing the skin.

1. Tip the seat forward to see the battery.

2. Look at the side of the battery. The electrolyte

must be up to the Upper line (Figure 33).

Do not allow the electrolyte to fall below the

Lower line (Figure 33).

Figure 33

1. Vent caps

3. Lower line

2. Upper line

3. If the electrolyte is low, add the required

amount of distilled water; refer to Adding

Water to the Battery.

Adding Water to the Battery

The best time to add distilled water to the battery is

just before you operate the machine. This lets the

water mix thoroughly with the electrolyte solution.

1. Remove the battery from the tractor; refer to

Removing the Battery.

Important:

Never fill the battery with

distilled water while the battery installed in

the tractor. Electrolyte could be spilled on

other parts and cause corrosion.

2. Clean the top of the battery with a paper towel.

3. Remove the vent caps from the battery

4. Slowly pour distilled water into each battery

cell until the electrolyte level is up to the Upper

line (Figure 33) on the battery case.

Important:

Do not overfill the battery

because electrolyte (sulfuric acid) can

cause severe corrosion and damage to the

chassis.

5. Wait five to ten minutes after filling the battery

cells. Add distilled water, if necessary, until

the electrolyte level is up to the Upper line

(Figure 33) on the battery case.

6. Reinstall the battery vent caps.

28

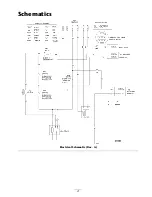

Summary of Contents for TimeCutter ZX440

Page 7: ...Slope Chart 7 ...

Page 41: ...Schematics Electrical Schematic Rev A 41 ...

Page 42: ...Notes ...

Page 43: ...Notes ...

Page 44: ......