6

Installing the Blower

Assembly

Parts needed for this procedure:

1

Blower assembly

Procedure

WARNING

An uncovered discharge opening allows the

lawn mower to throw objects toward you or

bystanders, resulting in serious injury. Also,

contact with the blade could occur.

•

Never operate the lawn mower without a

cover plate, a mulch plate, or a grass chute

and catcher.

•

Make sure that the grass deflector is

installed when you remove the grass chute

and catcher.

Important:

Install the side-discharge chute when

you remove the bagger and blower.

Important:

Save all the hardware and the

side-discharge chute.

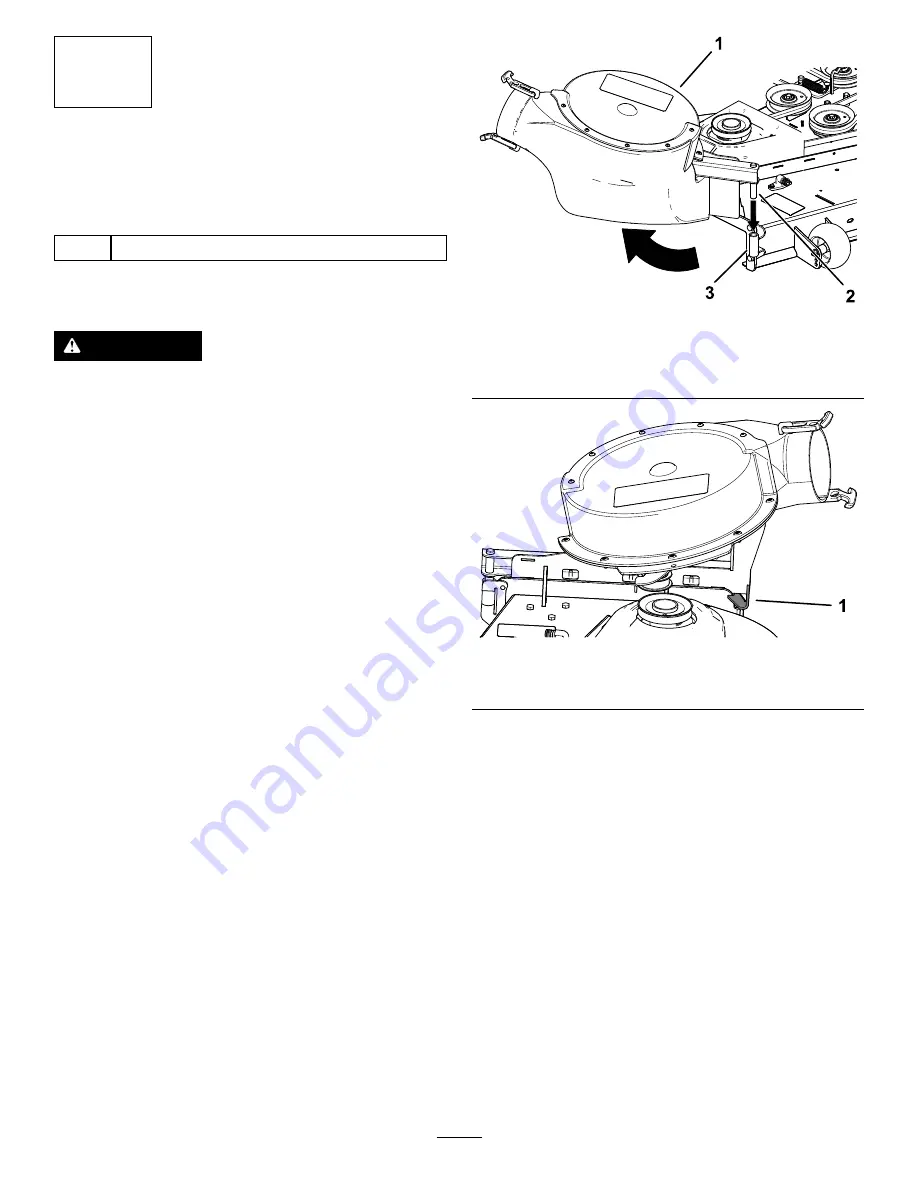

1.

If necessary, install the belt onto the blower

pulley (

).

2.

Insert the blower pivot pin into the blower

support and rotate the blower assembly inward

toward the machine (

Note:

The blower assembly should

automatically latch as shown in

g201514

Figure 13

1.

Blower assembly

3.

Blower support

2.

Blower pivot pin

g201893

Figure 14

1.

Blower latch

13