petrodiesel portion should be low or ultra low sulfur.

Observe the following precautions:

•

The biodiesel portion of the fuel must meet

specification ASTM D6751 or EN14214.

•

The blended fuel composition should meet ASTM

D975 or EN590.

•

Painted surfaces may be damaged by biodiesel

blends.

•

Use B5 (biodiesel content of 5%) or lesser blends

in cold weather.

•

Monitor seals, hoses, gaskets in contact with fuel

as they may degrade over time.

•

Fuel filter plugging may occur for a time after

converting to biodiesel blends.

•

Contact your distributor for more information on

biodiesel.

Filling the Fuel Tanks

Fuel tank capacity:

35 L (9.3 US gallons) per tank

1.

Park the machine on a level surface, engage the

parking brake, and lower the loader arms.

2.

Shut off the engine and remove the key.

3.

Remove the fuel cap.

4.

Fill the tank with fuel up to the filler neck.

5.

Install the cap.

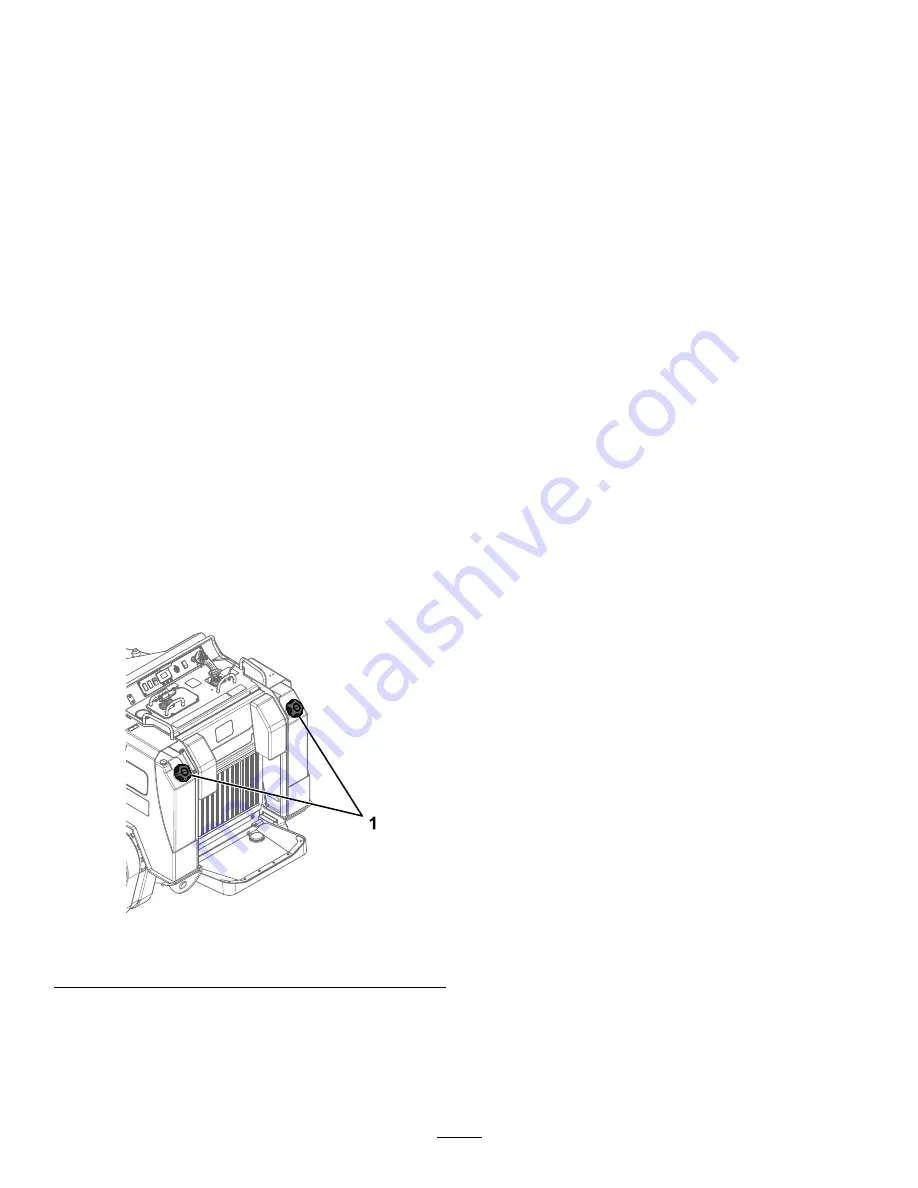

g303269

Figure 27

1.

Fuel tank caps

Performing Daily

Maintenance

Before starting the machine each day, perform the

Each Use/Daily procedures listed in the

(page 28)

.

Important:

Check the hydraulic-fluid level

and bleed the fuel system before starting the

engine for the first time; refer to

Hydraulic-Fluid Level (page 50)

and

Fuel System (page 38)

.

20