Gasoline and Oil

11

Using Stabilizer/Conditioner

Use a fuel stabilizer/conditioner in the machine to

provide the following benefits:

•

Keeps gasoline fresh during storage of 90 days

or less. For longer storage, drain the fuel tank.

•

Cleans the engine while it runs

•

Eliminates gum-like varnish buildup in the fuel

system, which causes hard starting

IMPORTANT: Do not use fuel additives

containing methanol or ethanol.

Add the correct amount of gas stabilizer/conditioner

to the gas.

Note:

A fuel stabilizer/conditioner is most

effective when mixed with fresh

gasoline. To minimize the chance of

varnish deposits in the fuel system, use

fuel stabilizer at all times.

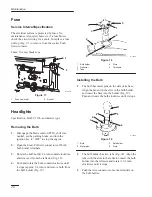

Filling the Fuel Tank

1.

Shut the engine off and set the parking brake.

2.

Clean around each fuel tank cap and remove the

cap. Add unleaded regular gasoline to both fuel

tanks, until the level is 1/4 to 1/2 inch (6 mm to

13 mm) below the bottom of the filler neck. This

space in the tank allows gasoline to expand. Do

not fill the fuel tanks completely full.

3.

Install fuel tank caps securely. Wipe up any

gasoline that may have spilled.

4.

Fuel gauge is located in right side tank.

Check Engine Oil Level

Before you start the engine and use the machine,

check the oil level in the engine crankcase; refer to

Checking Oil Level, page 34.

Summary of Contents for Wheel Horse 16-38 XLE

Page 7: ...Safety 5 Slope Chart Read all safety instructions on pages 2 8...

Page 8: ...6...

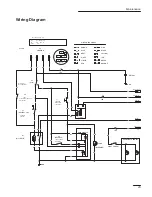

Page 27: ...Maintenance 25 Wiring Diagram...

Page 52: ......