Maintenance

30

1

2

1867

Figure 29

1.

Paper element

2.

Rubber seal

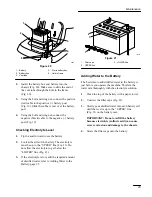

Installing the Foam and Paper Elements

IMPORTANT: To prevent engine damage,

always operate the engine with the complete

foam and paper air cleaner assembly

installed.

1.

Carefully slide the foam element onto the paper

air cleaner element (Fig. 26).

2.

Slide the air cleaner assembly onto the long rod.

Now screw the rubber nut finger-tight against the

air cleaner (Fig. 27).

Note:

Make sure the rubber seal is flat

against the air cleaner base.

3.

Install the air cleaner cover and knob (Fig. 25).

Tighten the knob snugly.

4.

Close the hood.

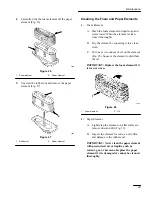

Engine Oil

Service Interval/Specification

Change oil:

•

After the first 5 operating hours.

•

After every 25 operating hours.

Note:

Change oil more frequently when

operating conditions are extremely

dusty or sandy.

Oil Type: Detergent oil (API service SF, SG or SH)

Crankcase Capacity:

48 oz/1-1/2 qt (1400 cc/1.4 l)

when filter is not changed;

56 oz (1700 cc/1.7 l)

when filter is changed.

Viscosity: See table below

F

–20

0

20

40

60

80

100

°

C

–30

°

–20

–10

0

10

20

30

40

USE THESE SAE VISCOSITY OILS

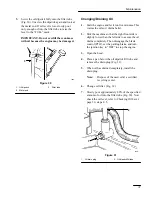

Checking Oil Level

1.

Park the machine on a level surface, disengage

the blade control (PTO), set the parking brake,

and turn the ignition key to “OFF” to stop the

engine.

2.

Open the hood.

3.

Clean around the oil dipstick (Fig. 30) so dirt

cannot fall into the filler hole and damage the

engine.

4.

Unscrew the oil dipstick and wipe the metal end

clean (Fig. 30).

Summary of Contents for Wheel Horse 17-44 HXL

Page 7: ...Safety 5 Slope Chart Read all safety instructions on pages 2 4...

Page 8: ...6...

Page 24: ...Maintenance 22 Wiring Diagram...

Page 38: ......

Page 39: ......