20

Maintenance

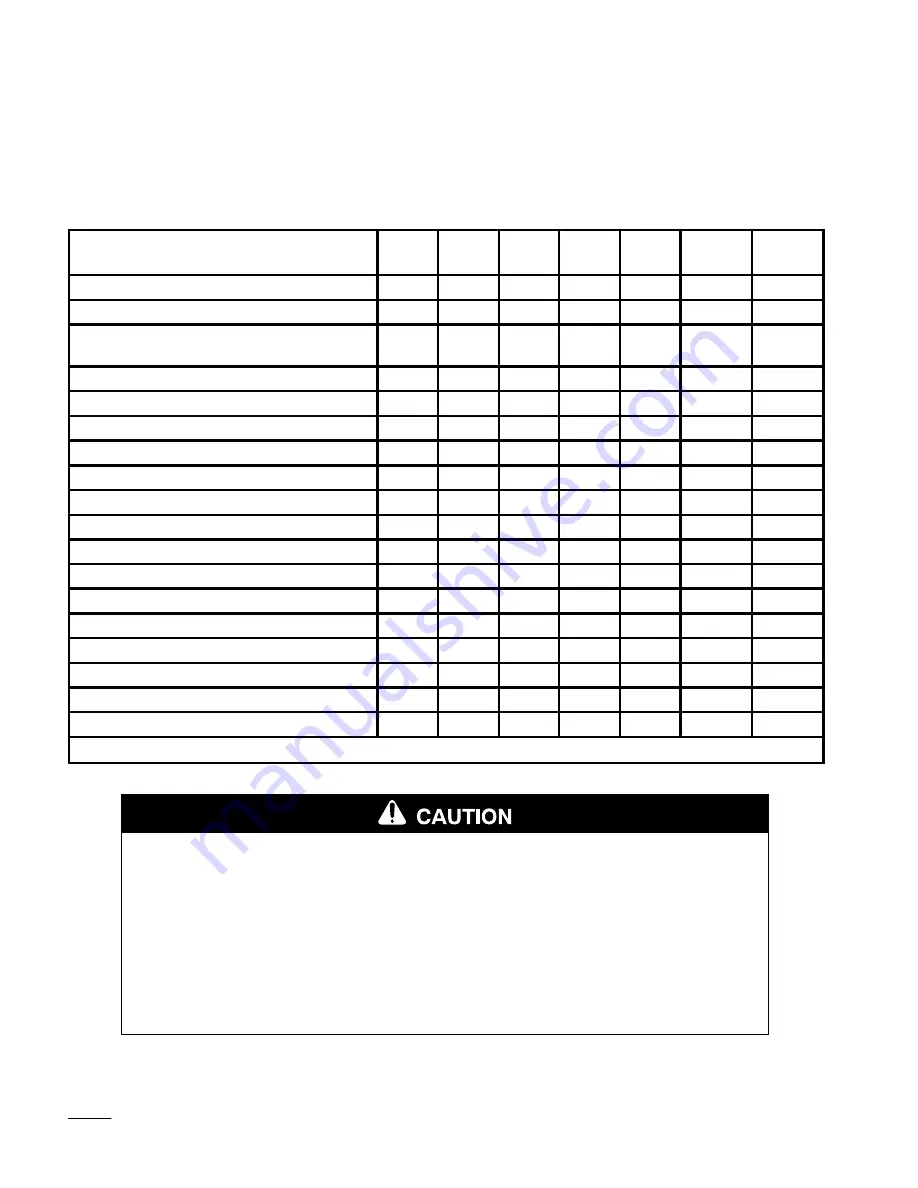

Service Interval Chart

Service Operation

Each

Use

5

Hours

25

Hours

50

Hours

100

Hours

Storage

Service

Spring

Service

Oil—check level

X

Oil—change*

Initial

X

Oil Filter—change* (200 hours, every

other oil change or yearly)

X

X

Safety System—check

X

X

Brake—check

X

X

X

X

Chassis—grease*

X

X

Foam Air Cleaner—service*

X

X

Paper Air Cleaner—replace*

X

X

Spark Plug(s)—check

X

X

X

Belts—check for wear/cracks

X

X

Gasoline—drain

X

Engine—clean outside

X

X

X

Chipped Surfaces—paint

X

Battery—check electrolyte

X

X

X

Battery—charge, disconnect cables

X

Fuel Filter—replace

X

X

Tires—check pressure

X

X

X

Front Wheels–check toe-in

X

X

* More often in dusty, dirty conditions

POTENTIAL HAZARD

•

If you leave the key in the ignition switch, someone could start the engine.

WHAT CAN HAPPEN

•

Accidental starting of the engine could seriously injure you or other bystanders.

HOW TO AVOID THE HAZARD

•

Remove the key from the ignition switch and pull the wire(s) off the spark plug(s)

before you do any maintenance. Also push the wire(s) aside so it does not

accidentally contact the spark plug(s).

Summary of Contents for Wheel Horse 265-6

Page 7: ...Safety 5 Slope Chart Read all safety instructions on pages 2 4 ...

Page 8: ...6 ...

Page 39: ...Maintenance 37 Wiring Diagram ...

Page 43: ......