Check Before Operating

12

Adding Fuel

The engine runs on clean, fresh diesel fuel with a

minimum cetane rating of 40. Purchase fuel in

quantities that can be used within 30 days to assure

fuel freshness.

Use summer grade diesel fuel (No. 2–D) at

temperatures above 20

F (–7

C) and winter grade

diesel fuel (No. 1–D or No. 1–D/2–D blend) below

20

F (–7

C). Use of winter grade diesel fuel at

lower temperatures provides lower flash point and

pour point characteristics, therefore easing startability

and lessening chances of chemical separation of the

fuel due to lower temperatures (wax appearance,

which may plug filters).

Use of summer grade diesel fuel above 20

F (–7

C)

will contribute toward longer life of the pump

components.

IMPORTANT: Do not use kerosene or

gasoline instead of diesel fuel. Failure to

observe this caution will damage the engine.

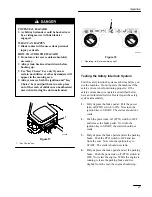

POTENTIAL HAZARD

•

Under certain conditions, fuel is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

•

A fire or explosion from fuel can burn you,

others, and cause property damage.

HOW TO AVOID THE HAZARD

•

Use a funnel and fill the fuel tank outdoors,

in an open area, when the engine is cold.

Wipe up any fuel that spills.

•

Do not fill the fuel tank completely full.

Add fuel to the fuel tank until the level is

1/4” to 1/2” (6 mm to 13 mm) below the

bottom of the filler neck. This empty space

in the tank allows fuel to expand.

•

Never smoke when handling fuel, and stay

away from an open flame or where fuel

fumes may be ignited by a spark.

•

Store fuel in an approved container and

keep it out of the reach of children. Never

buy more than a 30-day supply.

1.

Park the machine on a level surface, disengage

the power take off (PTO), set the parking brake,

lower the attachment lift, and turn the ignition

key to “STOP” to stop the engine. Remove the

ignition key.

2.

Clean around the fuel tank cap and remove the

cap. Use a funnel and add fuel until the fuel

level is 1/4 to 1/2 inch (6 mm to 13 mm) below

the bottom of the filler neck. This space in the

tank allows for expansion of the fuel. When

filling the tank, make sure that the machine is on

a level surface so that adequate air space is

allowed. Do not fill the fuel tank completely.

3.

Install the fuel cap securely. Wipe up any fuel

that may have spilled.

4.

If possible, fill the fuel tank after each use. This

will minimize possible buildup of condensation

inside the fuel tank.

Summary of Contents for Wheel Horse 523Dxi

Page 8: ...Safety 6...

Page 9: ...Safety 7 Slope Chart Read all safety instructions on pages 3 5...

Page 10: ...8...

Page 59: ...57...