Maintenance

24

Changing/Draining Oil

1.

Start the engine and let it run five minutes. This

warms the oil so it drains better.

2.

Park the machine so that the drain side is slightly

lower than the opposite side to assure the oil

drains completely. Then disengage the power

take off (PTO), set the parking brake, and turn

the ignition key to “OFF” to stop the engine.

Remove the key.

3.

Place a pan below the oil drain. Remove the oil

drain cap (Fig. 17).

4.

When oil has drained completely, install the

drain cap.

Note:

Dispose of the used oil at a certified

recycling center.

1

m–3956

Figure 17

1.

Oil drain cap

5.

Slowly pour approximately 80% of the specified

amount of oil specified, page 23, into the filler

tube (Fig. 16). Now check the oil level; refer to

Checking Oil Level, page 23. Slowly add

additional oil to bring to “FULL” mark on

dipstick.

Change Oil Filter

Replace the oil filter every 200 hours or every other

oil change.

Note:

Change oil filter more frequently when

operating conditions are extremely

dusty or sandy.

1.

Drain the oil from the engine; refer to

Changing/Draining Oil, page 24.

2.

Remove the old filter and wipe the filter adapter

(Fig. 18) gasket surface.

3.

Pour new oil of the proper type in through the

center hole. Stop pouring when the oil reaches

the bottom of the threads. Allow a minute or two

for the oil to be absorbed by filter material.

4.

Apply a thin coat of new oil to the rubber gasket

on the replacement filter (Fig. 18).

m–1256

1

2

3

Figure 18

1.

Oil filter

2.

Gasket

3.

Adapter

5.

Install the replacement oil filter to the filter

adapter. Turn the oil filter clockwise until the

rubber gasket contacts the filter adapter, then

tighten the filter an additional 1/2 turn (Fig. 18).

6.

Fill the crankcase with the proper type of new

oil; refer to Changing/Draining Oil, page 24.

Summary of Contents for Z-320

Page 7: ...Safety 5 Slope Chart Read all safety instructions on pages 2 4 ...

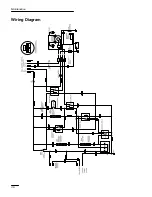

Page 38: ...Maintenance 36 Wiring Diagram ...

Page 43: ......