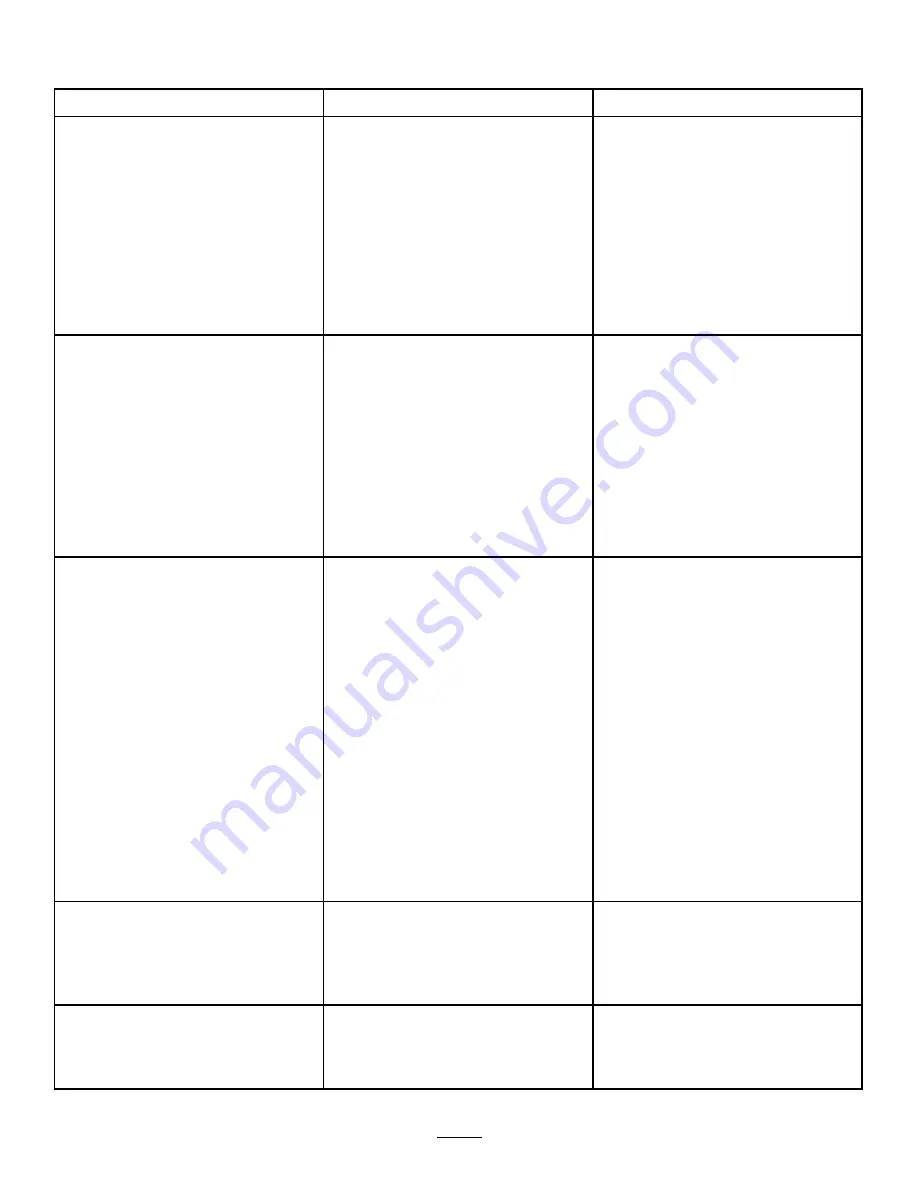

Troubleshooting

Problem

Possible Cause

Corrective Action

1. The engine is too hot.

1. Shut off the engine and let it cool.

2. There is a faulty valve in the fuel tank.

2. Contact an Authorized Service Dealer.

3. The air cleaner is dirty.

3. Make sure that the air cleaner and

precleaner are clean. Replace if

necessary.

4. The battery is not charged.

4. Charge or replace the battery.

5. The connections to the sensors

electronic-control unit (ECU) and fuel

injectors are not secured properly.

5. Contact an Authorized Service Dealer.

6. There is low voltage from the battery.

6. Ensure that you are using a good 12 V

battery and that it is fully charged.

The malfunction-indicator light (MIL)

comes on.

7. A fuse is blown.

7. Check and replace any blown fuses.

1. The blade-control switch (PTO) is

engaged.

1. Move the blade-control switch (PTO)

to the disengaged position.

2. The parking brake is disengaged.

2. Engage the parking brake.

3. The motion-control levers are not in

the N

EUTRAL

-

LOCK

position.

3. Ensure that the motion-control levers

are in the N

EUTRAL

-

LOCK

position.

4. The operator is not seated.

4. Sit on the seat.

5. The battery is dead.

5. Charge the battery.

6. The electrical connections are

corroded or loose.

6. Check the electrical connections for

good contact.

7. The fuse is blown.

7. Replace the fuse.

The starter does not crank.

8. The relay or switch is worn or

damaged.

8. Contact an Authorized Service Dealer.

1. The LPG tank is empty.

1. Change the LPG tank.

2. The oil level in the crankcase is low.

2. Add oil to the crankcase.

3. The throttle is not in the correct

position.

3. Be sure that the throttle control is

midway between the slow and fast

positions.

4. The air cleaner is dirty.

4. Clean or replace the air-cleaner

element.

5. The seat switch is not functioning

properly.

5. Check the seat-switch indicator.

Replace the seat if necessary.

6. The electrical connections are

corroded, loose, or damaged.

6. Check the electrical connections

for good contact. Clean the

connector terminals thoroughly with

electrical-contact cleaner, apply

dielectric grease, and make the

appropriate connections.

7. The relay or switch is worn or

damaged.

7. Contact an Authorized Service Dealer.

8. The spark plug is fouled or improperly

gapped.

8. Adjust or replace the spark plug.

The engine does not start, starts hard, or

fails to keep running.

9. The spark-plug wire is not connected.

9. Check the spark-plug wire connection.

1. The engine load is excessive.

1. Reduce the ground speed.

2. The air cleaner is dirty.

2. Clean the air-cleaner element.

3. The oil level in the crankcase is low.

3. Add oil to the crankcase.

The engine loses power.

4. The cooling fins and the air passages

above the engine are plugged.

4. Remove the obstruction from the

cooling fins and the air passages.

1. The engine load is excessive.

1. Reduce the ground speed.

2. The oil level in the crankcase is low.

2. Add oil to the crankcase.

The engine overheats.

3. The cooling fins and the air passages

above the engine are plugged.

3. Remove the obstruction from the

cooling fins and the air passages.

76

Summary of Contents for Z Master Professional 5000 Series

Page 13: ...decal136 5508 136 5508 1 Belt routing 13...

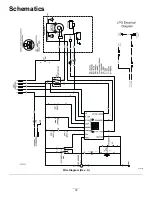

Page 78: ...Schematics g021490 Wire Diagram Rev A 78...

Page 79: ...Notes...