g001070

Figure 73

1.

Tracking knob

4.

Turn this way to track right.

2.

Hydraulic tank

5.

Turn this way to track left.

3.

Hydraulic pumps

Checking the Tire Pressure

Service Interval:

Every 50 hours/Monthly (whichever

comes first)

Maintain the air pressure in the front and rear tires

at 90 kPa (13 psi). Uneven tire pressure can cause

uneven cut. Check the tires when they are cold to get

the most accurate pressure reading.

g001055

Figure 74

Checking the Wheel Lug

Nuts

Check and torque the wheel lug nuts to 122 to 129

N∙m (90 to 95 ft-lb).

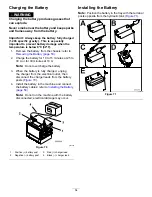

Torquing the Wheel Hub

Castle Nut

Service Interval:

After the first 100 hours

Every 500 hours thereafter

1.

Remove the cotter pin.

2.

Torque the castle nut to 319 N∙m (235 ft-lb).

3.

Continue to tighten the nut slowly until the next

slot aligns with the cross hole in the wheel motor

shaft.

4.

Insert the cotter pin and bend 1 tine over the

end of the shaft.

Note:

Do not use anti-seize on the wheel hub.

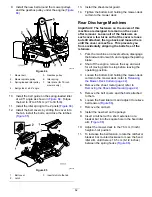

Adjusting the Caster-Pivot

Bearing

Service Interval:

Every 500 hours/Yearly (whichever

comes first)

1.

Park the machine on a level surface, disengage

the blade-control switch (PTO), and engage the

parking brake.

2.

Shut off the engine, remove the key, and wait

for all moving parts to stop before leaving the

operating position.

3.

Remove the dust cap from caster and tighten

the locknut (

4.

Tighten the locknut until the spring washers are

flat, and then back off a 1/4 turn to properly set

the preload on the bearings (

).

Important:

Make sure that the spring

washers are installed correctly as shown in

.

5.

Install the dust cap (

56

Summary of Contents for Z Master Professional 7000 Series

Page 2: ......

Page 84: ...Schematics g012068 Wire Diagram Rev A 82...

Page 86: ......

Page 177: ...Schaltbilder g012068 Schaltbild Rev A 91...

Page 270: ...Sch mas g012068 Sch ma de c blage Rev A 92...

Page 271: ...Remarques...

Page 272: ...Remarques...

Page 274: ......

Page 362: ...Schema s g012068 Elektrisch schema Rev A 88...

Page 364: ......