37

1. Move the machine onto a level surface and set the

parking brake.

2. Clean area around filler neck of hydraulic tank

(Fig. 40).

3

1

2

m–5615

4

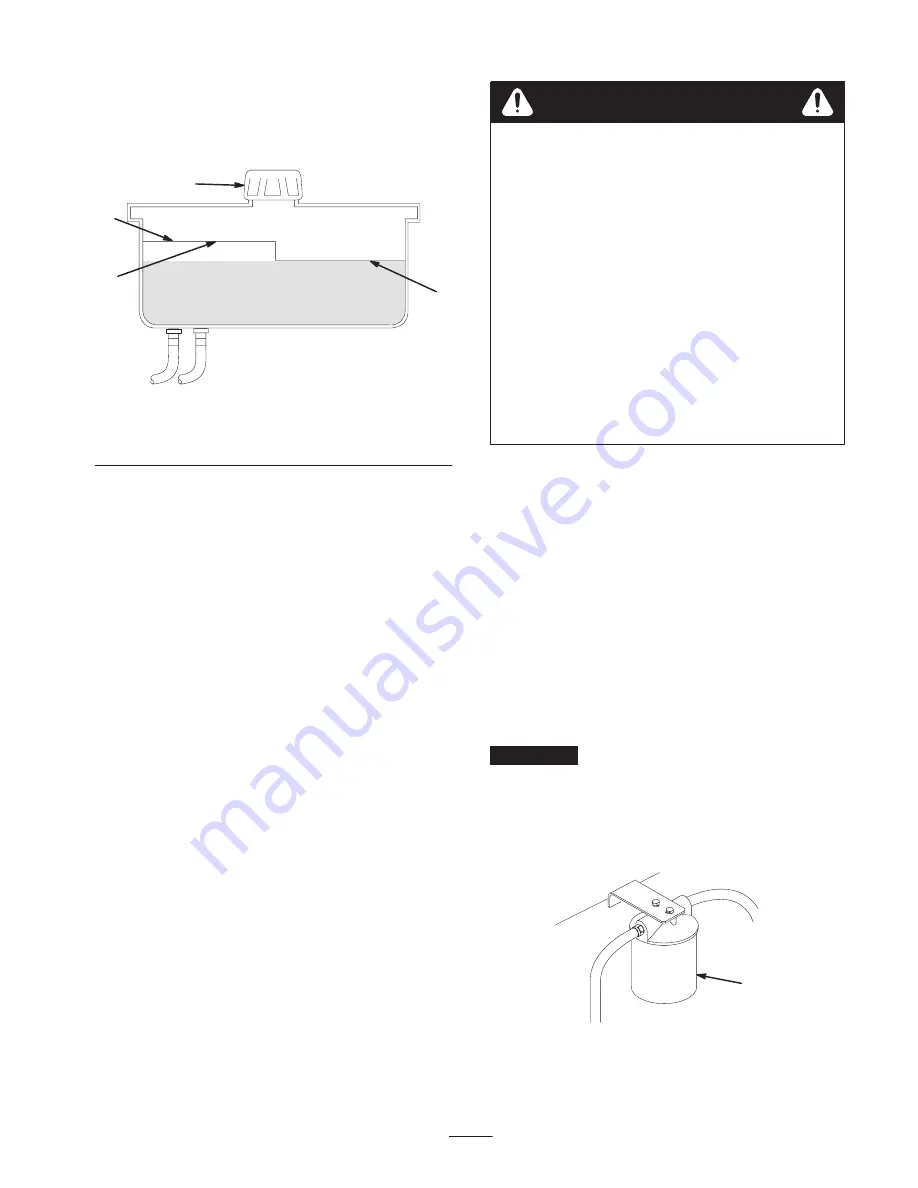

Figure 40

1.

Cap

2.

Baffle

3.

Cold fluid level—full

4.

Hot fluid level—full

3. Remove the cap from the filler neck and look inside to

check if there is fluid in the reservoir (Fig. 40).

4. If there is no fluid, add fluid to the reservoir until it

reaches the Cold level of the baffle.

5. Run the machine at low idle for 15 minutes to allow any

air to purge out of the system and warm the fluid. Refer

to Starting and Stopping the Engine on page 20.

6. Check the fluid level while the fluid is warm. The fluid

should be between the Cold and Hot levels.

7. If required, add fluid to the hydraulic tank.

Note: The fluid level should be to the top of the Hot

level of the baffle when the fluid is hot (Fig. 40).

8. Install cap on filler neck.

Hydraulic fluid escaping under pressure can

penetrate skin and cause injury.

•

If hydraulic fluid is injected into the skin, it

must be surgically removed within a few hours

by a doctor familiar with this type of injury;

otherwise, gangrene may result.

•

Keep your body and hands away from pin hole

leaks or nozzles that eject high-pressure

hydraulic fluid.

•

Use cardboard or paper to find hydraulic leaks.

•

Safely relieve all pressure in the hydraulic

system before performing any work on the

hydraulic system.

•

Ensure that all hydraulic fluid hoses and lines

are in good condition and all hydraulic

connections and fittings are tight before

applying pressure to the hydraulic system.

Warning

Replacing the Hydraulic Filter

Change the hydraulic filter:

•

After the first 8 operating hours

•

After every 200 operating hours

Use a summer filter above 32

°

F (0

°

C)

Use a winter filter below 32

°

F (0

°

C)

1. Disengage the PTO, move the motion control levers to

the neutral locked position, and set the parking brake.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

Important

Do not substitute an automotive oil filter for

a hydraulic filter; this can severely damage the hydraulic

system.

3. Place a drain pan under the filter, remove the old filter,

and wipe the filter adapter gasket surface clean

(Fig. 41).

1

m-4763

Figure 41

1.

Hydraulic filter