42

4. Tighten the locknut until the spring washers are flat,

then back off 1/4 turn to properly set the pre-load on the

bearings (Fig. 47).

Important

Ensure that the spring washers are installed

correctly as shown in Figure 47.

Checking the Wheel Hub

Slotted Nut

Check after every 500 operating hours.

The slotted nut needs to be torqued to 125 ft-lb (170 N

⋅

m).

1. Disengage the PTO, move the motion control levers to

the neutral locked position, and set the parking brake.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Remove the cotter pin.

4. Torque the slotted nut to 125 ft-lb (170 N

⋅

m) (Fig. 48).

3

m–4638

1

2

4

5

Figure 48

1.

Slotted nut

2.

Two threads or less

showing

3.

Hole in threaded shaft

4.

Washer (if needed)

5.

Slot

5. Check the distance from the bottom of the slot in the

nut to the inside edge of the hole.

Note: No more than 2 threads should be showing

(Fig. 48).

6. If more than 2 threads are showing, remove the nut and

install a washer between the hub and nut (Fig. 48).

7. Torque the slotted nut to 125 ft-lb (170 N

⋅

m) (Fig. 48).

8. Tighten the nut until the next set of slots line up with

the hole in the shaft (Fig. 48).

9. Install the cotter pin.

Leveling the Mower at Three

Positions

Important

There are only 3 measuring positions

needed to level the mower.

Setting Up the Machine

1. Position mower on a flat surface.

2. Disengage the PTO, move the motion control levers to

the neutral locked position, and set the parking brake.

3. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

4. Check tire pressure of all 4 tires. If needed, adjust them

to 13 psi (90 kPa)

5. Position the mower to the 3-inch (76 mm) height-of-cut

position.

6. Inspect the 4 chains; the chains need to have tension.

Note: Adjust the rear chains to the top of the slot, where

they are attached to the mower.

•

If one rear chain is loose, lower (loosen) the front

support arm on the same side. Refer to Adjusting the

Front-to-Rear Mower Pitch on page 43.

•

If one front chain is loose, raise (tighten) the front

support arm for that chain. Refer to Adjusting the

Front-to-Rear Mower Pitch on page 43.

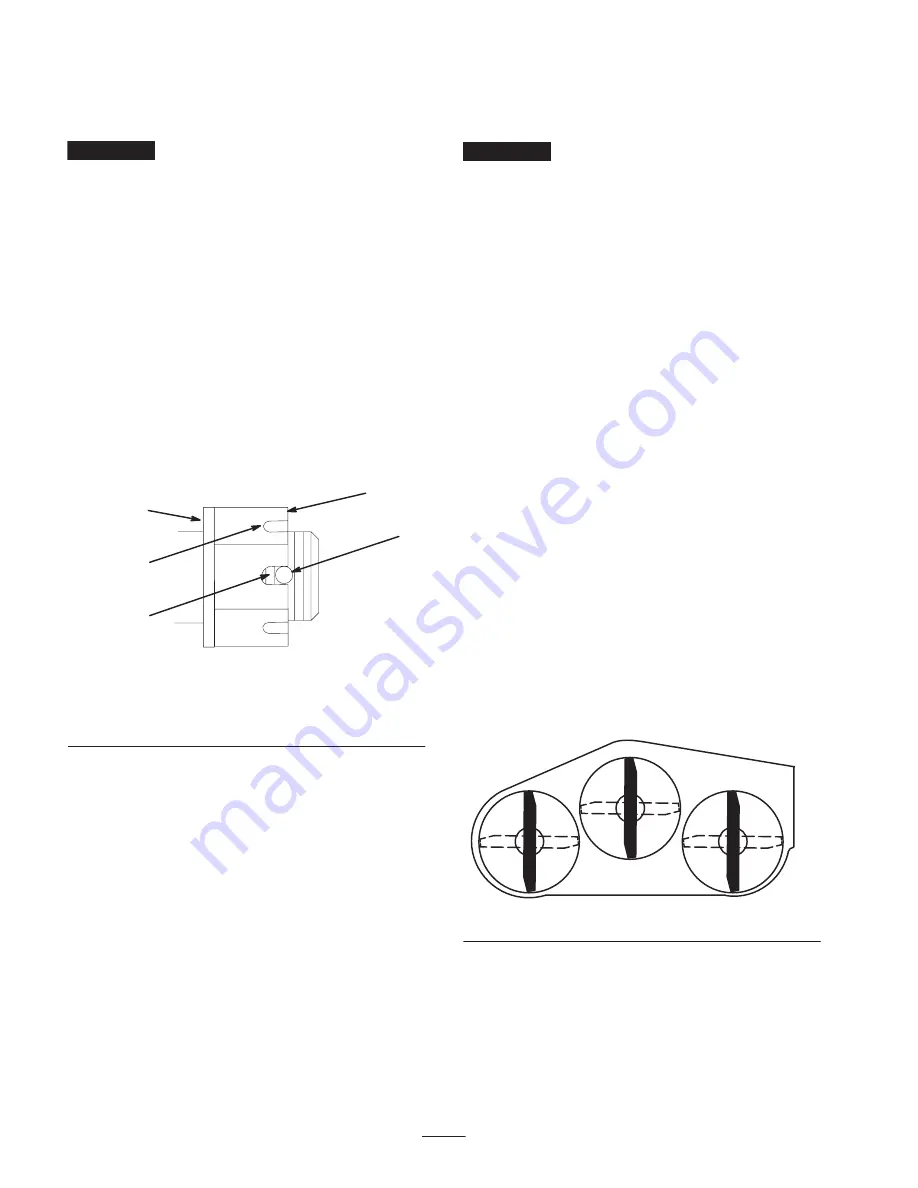

Leveling the Mower Side-to-Side

1. Position the right blade front to rear (Fig. 49).

Front

B

m–1078

C

Figure 49